May 21, 2025 | 15:24 GMT +7

May 21, 2025 | 15:24 GMT +7

Hotline: 0913.378.918

May 21, 2025 | 15:24 GMT +7

Hotline: 0913.378.918

TH true Milk's dairy cow herd of approximately 70,000 heads is served by "5-star farms" and "5-star kitchens", with all feed, water, vitamins, and minerals meeting European quality standards, experiencing standard inspection and traceability before use, and being controlled by leading modern machinery.

Mr. Tal Cohen, General Director of TH Milk Food Joint Stock Company, received the award "Best Livestock Feed Producer for Ruminants in 2023".

In mid-October 2023, TH Group received good news when it continued to be honored with the two highest prizes in the Vietnamese livestock industry awarded by the Ministry of Agriculture and Rural Development: "Best Livestock Feed Producer for Ruminants” and "Best Dairy Farm in 2022-2023".

Participating in the dairy farming and milk processing industry since 2009, TH operates a closed production process from grassland to milk glass, in which producing feed for dairy cows is an important intermediate stage in the process that creates the world-class quality of TH true Milk.

“The ingredients, quality, and origin of feed raw materials for TH dairy cows are fully analyzed before creating the nutritional formula to ensure that TH dairy cows always eat well, eat truly, and eat enough, neither too much nor too little. We always comply and do it truly and scientifically right from the starting point of the process", said Ms. Vy Thi Thu Hang, Director of the Center for Dairy Feed and Nutrition at TH Group, the unit that was just awarded the “Best Livestock Feed Producer for Ruminants in Vietnam in 2023” prize.

Overview of the Center for Feed and Nutrition at TH Group, where the most specialized work in the dairy farming industry is implemented.

The Center for Feed and Nutrition at TH Group is implementing the most specialized work in the dairy farming industry. Here, the laboratory is considered the "brain". TH's nutritionists have deployed software to simulate the cow's digestive system to accurately determine the best suitable indicators and raw materials for ruminants’ digestive characteristics. High-tech equipment and machinery are invested in and applied to build a separate and optimal nutritional formula for dairy cows.

“Cows have a diet formula, a formula to support near-bearing days, and the amount and method of supplementing vitamins and minerals in the postpartum period, etc. All are closely inspected and evaluated," Ms. Thu Hang shared.

To serve the dairy cow herd of approximately 70,000 heads at TH Farm, every day the two feed factories of the Center for Feed and Nutrition must produce and mix about 2,000 tons of feed. All stages are carried out by modern machinery and controlled via a computer system.

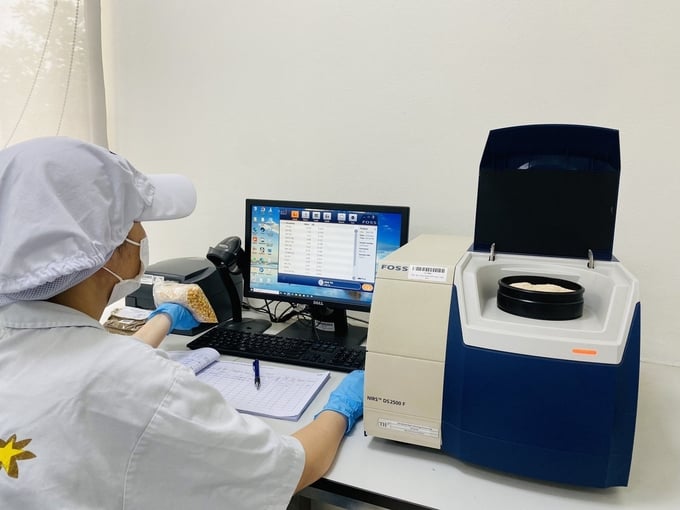

The ISO 17025 standard laboratory of the TH’s Center for Feed and Nutrition is operating the world's most modern near-infrared (NIR) spectrometer.

Particularly for quality control, from input raw materials to finished feed products, TH applies international and European standards. Standing out in the ISO 17025 standard laboratory system of the Center for Feed and Nutrition is the near-infrared (NIR) spectrometer for food analysis.

“The decision to invest in near-infrared (NIR) technology in quality control means that TH is owning the world's leading technology to serve the cow herd and protect the environment. With this technology, all of TH's nutritional analysis samples for dairy cows reach almost absolute accuracy.

The great advantage of NIR technology is that it is not necessary to use laboratory chemicals; we just need to put the sample into the machine and scan with infrared. The machine will give the results of more than 60 nutritional indicators in just one test. Thus, we both work effectively and contribute to protecting the environment in the Group’s direction of green development—Appreciating Mother Nature," said Mr. Ho Xuan Dien, Quality Control Supervisor, Quality Assurance Department at TH Dairy Food Joint Stock Company.

The corn sample is scanned with a NIR spectrometer and gives accurate results in just a few seconds.

“Previously, when analyzing samples, some indicators took 2 hours to analyze; even some took half a day to a day. But now, the near-infrared machine only scans and gives results immediately. Waiting time for results is no longer counted in minutes or hours, but in seconds,” Ms. Thu Hang proudly said.

Not only does it strictly control quality indicators so that the nutrition department can create the fastest and most optimal formula for the cow herd on the farm, but the NIR spectrometer also helps TH detect batches of raw materials that do not meet quality standards as committed by the supplier or as requested by TH. With scientific evidence that is clear and consistent with international standards, the rate of raw materials that TH detected as lacking standards and refused international suppliers is 2–3%/year.

“We have a standard program from the beginning and apply international standards, so after only 10 minutes of sampling, we can conclude that the supplier's cart and sample batch pass or fail. Even suppliers from Europe, when TH decided to return the goods because they did not meet standards, had to wholeheartedly agree," said Mr. Ho Xuan Dien.

To optimally operate the NIR analyzer, TH Group also cooperates with Dairy One Laboratory in the US, the world's leading laboratory for analyzing dairy cow feed. According to Dairy One, besides TH Group, Vietnam does not have any more ruminant feed producers cooperating with them.

Translated by Huyen Vu Thu

(VAN) The swamp in Pho Thanh is gradually being covered with red mangrove, creating a favorable environment for producing clean, high-quality salt.

(VAN) The trade turnover of agro-forestry-fishery products is growing significantly, along with investment cooperation commitments that are opening up new development directions between Vietnam and Russia.

(VAN) Khanh Hoa is investing over 545 billion VND to develop 240 hectares of high-tech marine aquaculture in order to guarantee a consistent supply of seafood exports and achieve the USD 1 billion target.

(VAN) Minister of Agriculture and Environment Do Duc Duy held a meeting with Soopakij Chearavanont, Chairman of C.P. Group, on May 15.

/2025/05/16/3800-0-nongnghiep-143756.jpg)

(VAN) Suntory PepsiCo Vietnam coordinated with the Ministry of Education and Training to implement an education program on water conservation, reaching nearly 1 million primary school students nationwide.

(VAN) Vietnam’s TH Group officially put its high-tech fresh milk processing plant into operation in the Russian Federation, marking a historic moment as the first TH true MILK cartons were produced in Russia.

(VAN) Use of high-quality broodstock and biotechnology is regarded as the most effective approach to ensuring sustainable and economically viable shrimp aquaculture ahead of climate change and the emergence of increasingly intricate disease patterns.