May 16, 2025 | 08:52 GMT +7

May 16, 2025 | 08:52 GMT +7

Hotline: 0913.378.918

May 16, 2025 | 08:52 GMT +7

Hotline: 0913.378.918

The inauguration ceremony was held in Moscow. Photo: TH Group.

The inauguration ceremony was held in Kaluga province, 100km from Moscow, and simultaneously broadcast to the Vietnam-Russia Business Forum in Moscow. It was part of General Secretary To Lam’s official visit to Russia at the invitation of President Vladimir Putin. The event was attended by high-ranking Vietnamese and Russian officials, including Russian Deputy Prime Minister Dmitry Chernyshenko.

Speaking at the forum, General Secretary To Lam congratulated both nations on the growing economic cooperation. He highlighted the vital role of businesses in fostering the bilateral ties and expressed confidence that future collaboration will extend beyond agriculture into areas such as investment, trade, science and technology, energy, and industry.

The plant’s launch ceremony was held simultaneously in Moscow and Kaluga. Senior leaders from Vietnam and Russia, along with business representatives, symbolically pressed the activation button for the new facility. The factory completes a crucial link in TH’s closed-loop production chain—“from green pastures to pure milk”—and will produce a range of high-quality dairy products under the TH True MILK brand.

The plant launch is a milestone in TH Group’s high-tech dairy farming and milk processing project in Russia, symbolizing the deepening cooperation between the two countries as they celebrate 75 years of diplomatic relations.

The TH plant spans nearly 15 hectares in the Kaluga special economic zone and is among Russia’s top-capacity milk processing facilities. The initial phase processes 500 tonnes of milk per day, with a goal of reaching 1,000 tons by 2026. It uses advanced technologies from Dutch company Bilfiner Tebodin and German firm GEA, and was built by Chinese state-owned construction giant CBMI Sinoma. Equipment for processing, packaging, and automation was sourced globally—from Germany, Sweden, Norway, Japan, Turkey, and China—and installed by international experts.

The special ceremony was witnessed and encouraged by General Secretary To Lam, accompanied by a high-level Vietnamese delegation and Russian Deputy Prime Minister Dmitry Chernyshenko, as part of the Vietnam–Russia Business Forum in Moscow. In picture, General Secretary To Lam delivering a speech at the forum, captured via live broadcast from Kaluga. Photo: TH Group.

The milk comes from TH’s high-tech farms in Moscow and Kaluga, where high-yield cows imported from the US produce an average of 40–41 litres per cow per day, with some yielding up to 104 litres. TH’s raw milk has been rated “top-tier” in Russia and purchased by major dairy firms like Danone and PepsiCo.

The Kaluga plant offers both traditional Russian dairy staples—pasteurized and UHT milk, Smetana, yoghurt, Kefir, Ryazhenka, butter, cheese, ice cream—and innovative health-oriented products targeting non-communicable diseases like obesity and diabetes. These are tailored to local tastes while incorporating TH’s signature creative approach.

After completing phase one, TH plans to build farm K2 in Kaluga and expand to Primorye (Far East) and the Republic of Bashkortostan. Products from the Russian plant will serve the 145-million-strong domestic market and be exported to BRICS and Asia-Pacific countries. TH also aims to produce internationally certified organic products in Russia.

TH is pioneering a closed-loop high-tech agricultural model in Russia, integrating livestock management, veterinary care, feed production, and dairy processing using advanced technologies. This model not only boosts productivity and milk quality but also helps modernise Russia’s agriculture sector, supporting the country’s national strategy for “Digital Agriculture.”

According to Hero of Labour Thai Huong, agriculture is the foundation of a nation and a sector closely tied to the livelihoods of millions. The Russian Federation possesses vast agricultural advantages and is fully capable of ensuring food security and safety. Pictured: Ms. Thai Huong at the TH dairy plant in Kaluga. Photo: TH Group.

The Russian government has strongly supported dairy development with the highest level of agricultural subsidies, estimated at 81 billion rubles in 2024. Policies include low-interest loans, capital investment reimbursement (30–42%), tax incentives, export freight subsidies, and per-unit production grants.

TH’s success in Kaluga has become a showcase of economic cooperation and people-to-people diplomacy. The project has revitalised tens of thousands of hectares of abandoned farmland in Kaluga and Moscow, created over 500 jobs, and contributed to agricultural restructuring in the region.

Russian President Vladimir Putin has repeatedly praised TH and founder Thai Huong for her strategic foresight, calling her a “brilliant entrepreneur.” During his visit to Vietnam, he highlighted TH as a model enterprise that successfully capitalised on investment opportunities in Russia.

Kaluga province, home to TH’s plant, has been designated a dairy development hub in Russia. By 2030, the region aims to produce 1 million tonnes of milk annually—a 40% increase from current levels. TH’s plant helps address the province’s shortfall in processing capacity and strengthens its position as a “milk granary.”

The product range of TH’s fresh milk processing plant in Kaluga is highly diverse, spanning traditional Russian dairy products such as pasteurised and UHT milk, Smetana, yoghurt, kefir, ryazhenka, butter, cheese, and ice cream, to non-traditional, health-focused items. Photo: TH Group.

Milk and dairy consumption in Russia reached its highest level in 28 years in 2024, at around 250kg per capita per year, exceeding domestic supply. This presents opportunities for producers like TH, whose high-quality milk and diverse product lines cater to evolving consumer preferences. Russian consumers now favour value-added products like cheese, yoghurt, low-fat items, and convenient small-sized packaging.

Russian agriculture, especially dairy, is pivoting toward automation, food safety, and efficiency—areas where TH has already excelled. TH's comprehensive understanding of local conditions and unwavering effort have helped the project succeed and contributed to broader industry reform.

TH Group's milk processing plant in Kaluga. Photo: TH Group.

In Vietnam, TH is known for turning agriculture into a national brand with global reach—embodying the spirit of “a glass of milk to rejuvenate the nation.” In Russia, the group has maintained that ethos, combining professionalism, technological excellence, and humanistic values to create a landmark project.

Translated by Linh Linh

(VAN) Use of high-quality broodstock and biotechnology is regarded as the most effective approach to ensuring sustainable and economically viable shrimp aquaculture ahead of climate change and the emergence of increasingly intricate disease patterns.

(VAN) Carbon farming is a form of agricultural practices that helps absorb more greenhouse gases than it emits, through smart management of soil, crops, and livestock.

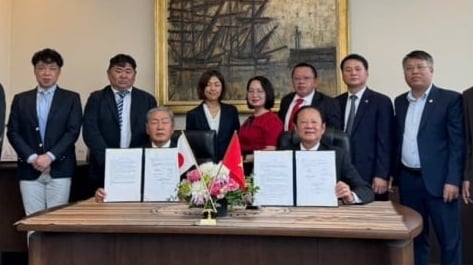

(VAN) This is a key content of the Memorandum of Understanding recently signed between the Vietnam Fisheries Society and Kunihiro Inc of Japan.

(VAN) To achieve the goal, local authorities and businesses in Kon Tum province have fully prepared the necessary conditions for the new Ngoc Linh ginseng planting season.

(VAN) Jiangsu province is gearing up to host training programs in Phnom Penh, the capital of Cambodia, this year to establish the Fish and Rice Corridor.

(VAN) Le Hoang Minh, representing Vinamilk, shared the company's experience in energy saving and green energy transition for production at a workshop held during the P4G Summit.