May 22, 2025 | 14:57 GMT +7

May 22, 2025 | 14:57 GMT +7

Hotline: 0913.378.918

May 22, 2025 | 14:57 GMT +7

Hotline: 0913.378.918

On November 30, the National Agricultural Extension Centre (NAEC) in collaboration with Hai Phong Department of Agriculture and Rural Development organized an online seminar for summarizing the project "Designing intensive shrimp farming model using Biofloc technology associated with consumption in the northern provinces"

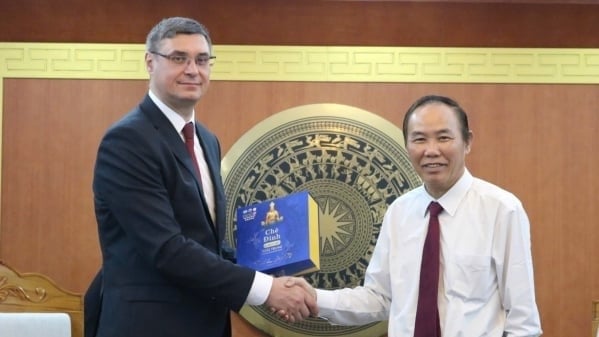

Representatives from NAEC and five provinces and cities participating in the project attended the virtual seminar. Photo: Dinh Muoi.

Representatives from the NAEC, and the provincial agricultural extension center of Thanh Hoa, Quang Ninh, Thai Binh and Nam Dinh attended the seminar.

The Biofloc-applied shrimp farming project will be carried out from March to December 2021 on 5,883 hectares in Hai Phong, Quang Ninh, Thai Binh, Nam Dinh and Thanh Hoa. Each shrimp farming model sized 1-1.5 ha on average. In phase 1, the experimental density was 1,200 baby shrimps per square meter. The survival rate reached above 90% and the length of farming was 20-25 days. In phase 2, the density was 120 baby shrimps per square meter, the survival rate reached above 75% and the length of farming was 65-80 days.

The white-legged shrimp farm with the application of BFT could earn a profit of VND1.2 billion per hectare on average, 63% above the conventional shrimp farm.

In the third year, the intensive shrimp farming model using BFT associated with consumption has helped change shrimp farmers' mindsets, motivating them to adopt new technologies for sustainable development.

The farmers have been aware of important benefits from the technology such as the reduction in costs of feed and chemicals, lower risk of disease infections, increased survival rate of baby shrimps and high-quality products for consumers.

Monthly tests and supervisions conducted by technical officers showed that farmed shrimps reached the highest growth rate in the phase 1. Especially shrimps raised in BFT- adopted indoor shrimp hatchery where environmental conditions were well-controlled could reach size of 700-1,000 pieces per kilo and the survival rate could be 90-92%.

Moreover, thanks to controlled environmental conditions and diseases the project has created secured quality products for consumers and targeting foreign markets.

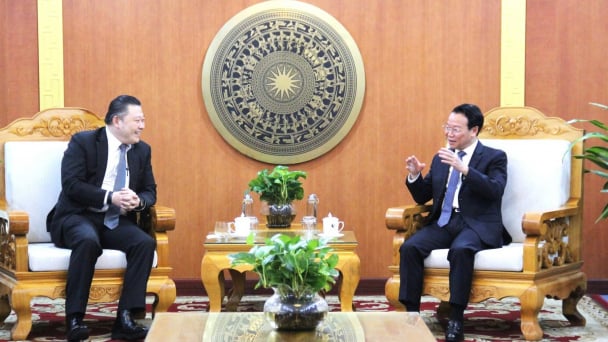

The seminar on the morning of November 30. Photo: Dinh Muoi.

Vu Van Tin, a shrimp farmer in Vinh Quang commune, Tien Lang district said: "Previously we applied traditional methods in raising shrimps so we couldn't control environmental elements and disease infections. As a result, feed conversion ratio (FCR) was high while the growth and survival rates were low."

On the other hand, due to changing climate and water pollution there was a high chance of complex disease outbreaks leading to low production and uncertain income. With the application of BFT the problems shrimp farmers used to face before are now solved. The length of farming and input costs have been reduced while the economic efficiency has increased significantly.

"My shrimp farm has adopted BFT since 2020 on an area of 4,000 square meters. We could harvest shrimp after around 90 days and shrimps could reach a size of 48-50 pieces per kilo. The survival rate was above 70%. We could earn a profit of VND500-600 million per two crops each year" said Tin.

"The project has led to a change in the shrimp farmers' mindsets to adopt advanced technologies to shrimp production, thereby reducing environment pollution and disease infections, lowering FCR and input costs along with increasing survival rate. Moreover, farmers can raise four crops per year instead of two crops as in the past. In addition, the quality of the product has been improved, meeting the standards of safety and satisfying market demand. Thanks to that economic efficiency per production unit is higher," said Dang Thi Thanh, Head of the Fisheries Office under Hai Phong's Agricultural Extension Center.

During the implementation of the project, several agencies such as the provincial agricultural extension center of Hai Phong and Quang Ninh required seed and material suppliers to make a commitment to buy shrimps from the participants. This would be a win-win situation.

Shrimp farmers could earn a big profit by applying Biofloc technology. Photo: CTV.

The real-world results showed that the companies honoured their commitments. Khoa Thanh Company Limited has bought 30.5 tons and 20.159 tons of shrimp in Hai Phong and Nam Dinh respectively.

In Thanh Hoa, Thanh Hoa Investment and Agriculture Development NT Joint Stock Company has bought 20.72 tons of shrimp from aquaculture farmers. Khoa Thanh Co.Ltd has cooperated with Quang Ninh Agricultural Technology Co.Ltd to buy more than 18.4 tons of shrimp from Quang Ninh farmers.

In Thai Binh, Hong Tien Commune's Fisheries Production, Business and Service Cooperative has purchased more than 21 tons of shrimp from local farmers. The commitment like this has helped farmers feel assure and avoid price squeezing.

Translated by Mai Tham

(VAN) CJ Feed&Care officially launched the FCR improvement campaign called “2025 Find Challenge Reach” in April 2025. In Vietnam, this campaign is implemented by CJ Vina Agri.

(VAN) The swamp in Pho Thanh is gradually being covered with red mangrove, creating a favorable environment for producing clean, high-quality salt.

(VAN) The trade turnover of agro-forestry-fishery products is growing significantly, along with investment cooperation commitments that are opening up new development directions between Vietnam and Russia.

(VAN) Khanh Hoa is investing over 545 billion VND to develop 240 hectares of high-tech marine aquaculture in order to guarantee a consistent supply of seafood exports and achieve the USD 1 billion target.

(VAN) Minister of Agriculture and Environment Do Duc Duy held a meeting with Soopakij Chearavanont, Chairman of C.P. Group, on May 15.

/2025/05/16/3800-0-nongnghiep-143756.jpg)

(VAN) Suntory PepsiCo Vietnam coordinated with the Ministry of Education and Training to implement an education program on water conservation, reaching nearly 1 million primary school students nationwide.

(VAN) Vietnam’s TH Group officially put its high-tech fresh milk processing plant into operation in the Russian Federation, marking a historic moment as the first TH true MILK cartons were produced in Russia.