May 17, 2025 | 07:58 GMT +7

May 17, 2025 | 07:58 GMT +7

Hotline: 0913.378.918

May 17, 2025 | 07:58 GMT +7

Hotline: 0913.378.918

According to Assoc. Prof. Dr. Bui Quang Thuat, cinnamon essential oil processing technology is still backward.

According to the Vietnam Association of Oils, Aromas and Cosmetics (VOCA), the cinnamon essential oil industry is an industry with great development potential because the world's demand for cinnamon essential oil is very high and supply is always insufficient. The reason for the insufficient supply is that cinnamon is only commonly grown in a few Asian countries, including Vietnam.

Vietnam is the world's leading cinnamon producer. According to statistics from the Department of Forestry (Ministry of Agriculture and Rural Development), the whole country has about 180,000 ha of cinnamon-growing land, concentrated in provinces such as Lao Cai (about 53,000 ha), Yen Bai (about 81,000 ha), and Quang Nam (about 53,000 ha). These three provinces account for about 70% of the total cinnamon area in the country.

Annual cinnamon bark reserves are estimated at about 900,000–1.2 million tons. The average cinnamon yield is 70,000–80,000 tons/year. The main export markets for Vietnamese cinnamon are India and the US.

Despite large cinnamon reserves, the export value is still not commensurate. Vietnam's cinnamon export value in 2020 reached USD 245 million, but by 2023, this number stopped at about USD 260 million. The main reason is due to technical barriers and failure to meet essential oil quality standards.

Currently, the cinnamon-growing area continues to increase across the country. In some places, people grow spontaneously without planning. In addition, most of the main cinnamon-growing provinces currently focus on expanding their areas instead of investing in quality, processing, and market expansion. A small part of the 180,000 ha of cinnamon nationwide is recognized as an organic product.

The Department of Forestry points out that the processing capacity of the production unit also affects the value of the cinnamon industry. Most cinnamon bark processors buy directly from collectors and perform both rough processing (sieving, sorting, peeling, and drying) and fine processing (cutting and grinding, removing metals and residues, and packaging).

Due to the specificity of the cinnamon industry, units mainly operate under a family-based, small-production model. Financial resources, as well as science and technology, are limited. Therefore, although it is considered a tree with high economic value, cinnamon in Vietnam only costs about VND 40 million/ha/year in terms of production value. Meanwhile, if exploited properly and seasonally, the value can increase to VND 200–300 million/ha/year.

Yen Bai is the province that grows the most cinnamon in the country, with an area of about 81,000 ha.

Assoc. Prof. Dr. Bui Quang Thuat, former Director of the Food Industries Research Institute, said that the most important part of the cinnamon tree is the cinnamon bark, which contains about 1–7% essential oil with the main ingredient being Cinnamonaldehyde. Cinnamon bark has a warm nature, a pleasant aroma, and a sweet and spicy taste, making it suitable as a spice for both sweet and salty foods.

According to Mr. Thuat, the world market for cinnamon products is very vibrant, with demand for cinnamon increasing steadily by about 7–8%/year. Cinnamon is used in the food industry, beverages, cosmetics, and a number of other fields.

Recognizing that there are still many opportunities for Vietnam's cinnamon industry, the associate professor also said that cinnamon growers still face challenges in the issue of varieties because there is no purebred, outstanding variety with high-quality essential oil. So the Cinnamonaldehyde content is usually below 80%, and the Coumarin content is 2–5%.

"Businesses and cinnamon growers have not implemented or complied with cinnamon quality management along the cinnamon product value chain. Technology and investment capital for deep processing to increase the value of cinnamon products have not really been paid attention to. Companies mainly operate in the commercial sector, paying little attention to building linkage chains with raw material farmers," said Mr. Thuat.

Besides, Vietnam does not have a national plan for cinnamon development; product announcement and traceability still encounter difficulties. The cinnamon product brand in the international market is still weak, and the market is unsustainable.

Heavy metal residues are also a challenge for cinnamon producers and processors. Some studies currently create biological products capable of reducing the heavy metal content in the cinnamon bark, but they have not been widely applied in production.

"In many businesses, the technology to pasteurize products from cinnamon bark is still backward, using batch pasteurization techniques or using boiling water directly in contact with cinnamon bark, so the effectiveness of killing microorganisms is not high. The long pasteurization time causes a lot of essential oil loss and also affects the color of the product, making it difficult to ensure export standards," Mr. Thuat emphasized.

People currently process cinnamon essential oil relatively manually, causing post-harvest losses.

In some advanced countries around the world, closed, continuous pasteurization technology using saturated steam on an automated equipment system has been widely applied. Powdered cinnamon is brought into and out of the system continuously on a conveyor belt.

The contact time is very short (20–40 seconds) with high-pressure steam at a temperature that can vary from 102°C to 122°C, helping kill microorganisms very effectively and reduce essential oil loss.

Considering Vietnam as a "green gold mine" of the essential oil extraction industry, Dr. Bui Thi Bich Ngoc at the Food Industries Research Institute assessed that Vietnam has many opportunities to develop this market, accounting for 1.6% of global output and 0.6% of global market share.

Besides traditional products such as anise and cinnamon essential oils, Vietnam also has the ability to export ginger, garlic, and pepper essential oils, whose quality is considered top in the world. According to Ms. Ngoc, the problem lies in market access due to a lack of information, technology, and human resources to meet the standards and quality of the importing country.

As for cinnamon essential oil, a representative of the Food Industries Research Institute said that for a long time, people have only focused on producing one product, originating from receiving cinnamon bark. However, in recent times, thanks to the development of science and technology such as steam-entrained distillation, extraction with common organic solvents or solvents with supercritical CO2, young leaves and branches, or by-products of the cinnamon bark making process, have been used in the distillation process.

"Traditional methods do not really focus on the steps of handling raw materials before distillation, such as incubation and grinding stages. Therefore, the efficiency of essential oil extraction is still low, only reaching about 50–60% compared to the amount of essential oil in the raw materials," Ms. Ngoc shared, adding that if only one type of product is produced, the phenomenon of price pressure may occur.

On that basis, Dr. Ngoc recommended diversifying output products to fully meet each market requirement, ensuring Cinnamonaldehyde content above 80% and Coumarin below 2%.

"It is necessary to invest in deep research to master the technology of fractional distillation of cinnamon essential oil. On the other hand, develop and master the technology of converting (semi-synthetic) high-value products such as Benzaldehyde from cinnamon essential oil. Thereby, diversify essential oil products and enhance the value of cinnamon essential oil in particular and cinnamon tree in general," emphasized Dr. Bui Thi Bich Ngoc.

Translated by Thu Huyen

(VAN) Vietnam’s TH Group officially put its high-tech fresh milk processing plant into operation in the Russian Federation, marking a historic moment as the first TH true MILK cartons were produced in Russia.

(VAN) Use of high-quality broodstock and biotechnology is regarded as the most effective approach to ensuring sustainable and economically viable shrimp aquaculture ahead of climate change and the emergence of increasingly intricate disease patterns.

(VAN) Carbon farming is a form of agricultural practices that helps absorb more greenhouse gases than it emits, through smart management of soil, crops, and livestock.

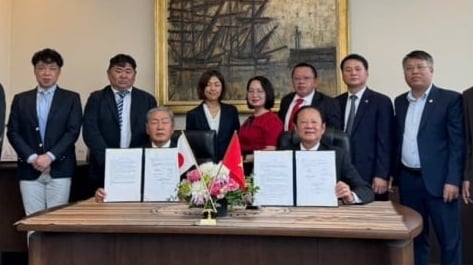

(VAN) This is a key content of the Memorandum of Understanding recently signed between the Vietnam Fisheries Society and Kunihiro Inc of Japan.

(VAN) To achieve the goal, local authorities and businesses in Kon Tum province have fully prepared the necessary conditions for the new Ngoc Linh ginseng planting season.

(VAN) Jiangsu province is gearing up to host training programs in Phnom Penh, the capital of Cambodia, this year to establish the Fish and Rice Corridor.

(VAN) Le Hoang Minh, representing Vinamilk, shared the company's experience in energy saving and green energy transition for production at a workshop held during the P4G Summit.