High-tech shrimp fingerling production complex worth VND 1,500 billion

Thứ Tư 27/03/2024 , 17:28 (GMT+7)(VAN) With the commitment to not using antibiotics in shrimp production, Viet Uc Group hopes to transfer clean shrimp farming technology to the people.

With its reputation for its commitment to not using antibiotics in shrimp production, Viet Uc Group hopes to transfer clean shrimp farming technology to the people.

Over the years, Viet Uc Group has invested more than VND 1,500 billion to pursue the direction of closing the shrimp industry value chain. In Bac Lieu, each membrane house area for raising and producing shrimp fingerlings and commercial shrimp is worth up to VND 7 to 8 billion.

Viet Uc Group considers proactively sourcing shrimp broodstock as a prerequisite for true high-tech shrimp fingerlings production.

Viet Uc Group is the first and only corporation to proactively program the genetics and selection of shrimp broodstock in Vietnam through exclusive cooperation with the CSIRO Institute (Commonwealth Scientific and Industrial Research Organisation). Currently, the Group supplies about 30% of shrimp fingerlings nationwide.

At the shrimp hatchery production area, Viet Uc produces broodstock that is clean of all pathogens as announced by the World Organization for Animal Health (formerly the Office International des Epizooties (OIE)) and complies with regulations of the Ministry of Agriculture and Rural Development, contributing to reducing risks of domestic shrimp industry's dependence on imported shrimp broodstock.

To ensure sustainable development, the business is committed to improving the water environment in aquaculture, reaching 100% no toxic waste in production.

Enterprises are especially interested in training and improving capacity in biosafety through organizing annual courses. Every day, technical experts feed the shrimp and check the health of farmed shrimp, then prepare detailed reports to handle problems promptly.

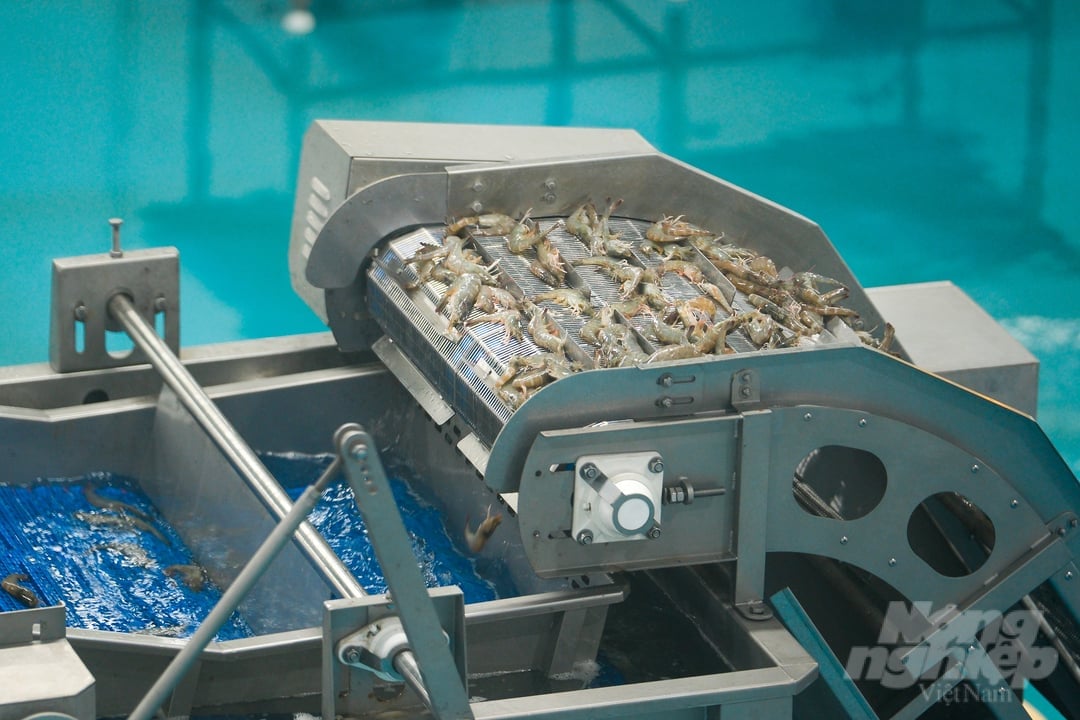

To close the value chain, the business has completed the seafood processing factory and put it into official operation in mid-2023. With a scale of 10 hectares, this is the first seafood factory in Vietnam to apply over 70% automatic technology.

Thanks to the input material being clean shrimp, combined with the world's leading advanced technologies, the Viet Uc Group's seafood processing system meets the most stringent standards from demanding import markets such as Korea, Japan, Australia, and Europe.

Mr. Trinh Trung Phi, Chief Operations Officer, Farmed shrimp & R&D Advisor - Hatcheries of Viet Uc Group, said that the business has begun implementing technology transfer programs for people, including models of off-grid farming and shrimp incubation without using shrimp. He expects that by 2025, Viet Uc Group will be able to connect people with the supply chain and professionalize the shrimp technology industry.

Translated by Tuan Huy

/2025/05/16/3800-0-nongnghiep-143756.jpg)