May 19, 2025 | 18:31 GMT +7

May 19, 2025 | 18:31 GMT +7

Hotline: 0913.378.918

May 19, 2025 | 18:31 GMT +7

Hotline: 0913.378.918

Phu Lam Ltd.Company has approximately 1,000 hectares, including 300 hectares of raw material area devoted to farming, a system of beef cattle farms fulfilling GlobalGAP requirements and functional subdivisions, as well as a modern factory system based on Australian standards.

Mr. Nguyen Minh Bch, the director of Phu Lam Ltd.Co, stated that the unit has implemented the project to raise breeding cows and beef cattle with a capacity of 40,000 cows per farming round as of March 2016.

Following construction, the project has entered operation with barns, a cow center, and clamps that fulfill Exporter Supply Chain Assurance System requirements (ESCAS). In addition, there are many auxiliary items to serve the breeding of around 15,000 cows.

Each cow is fitted with a chip so that Australian experts may watch and supervise the entire process from docking to slaughter. Photo: Tien Thanh.

"In addition to the development of 300 hectares for growing weeds, maize, and cassava to generate feeds, the initiative also promotes agricultural extension and coordination with nearby farmers to form a feeding material area," Mr. Bach explained.

Each batch of cows will be cared for and fattened for four to six months using a technical process to ensure that they are free of new diseases prior to being sent to slaughterhouses, where the same technologies and techniques must be used in accordance with Australian standards and evaluated by Australian experts. In addition, each cow is fitted with a chip so that Australian experts may watch and supervise the entire process from docking to slaughter.

In the past, Phu Lam firm has also added oyster shell powder to feed in order to boost their mineral content. Therefore, oyster shells are dried at 85 degrees Celsius to remove moisture and soften before being ground into powder.

When added to feed, oyster shells' organic calcium content helps cows boost milk output, meat production, bone development, and bone growth. This is beneficial for pregnant cows and young calves.

It is known that oyster shell powder mixed with concentrate is applied at a rate of 0.1 kg per head every day.

In addition, the company has invested in a production line for organic fertilizer made from cow manure and distributed on the market. Thanks to this, the farm's breeding environment is always clean and cold, ensuring the optimal development of the cows.

To optimize product quality, Phu Lam company always has strict requirements in each production stage, such as rejecting sick cows to produce cool meat, not allowing cows to fast for more than 12 hours prior to slaughter, and always bathing cows for 4 to 8 hours prior to slaughter to relax, reduce body temperature, and reduce the risk of infection in the meat.

Specifically, the slaughtering process poses the greatest danger of cross-contamination, which directly affects the preservation period and quality of the product. Therefore, all actions must be precise, and tools must be sanitized in boiling water after direct contact with the skin surface and before to contact with the carcass; never use water to clean the surface of the carcass when detecting stains, but rather remove the affected portion of meat.

Breeding farm of Phu Lam enterprise. Photo: Tien Thanh.

Beef will be chilled between 0 and 4 degrees Celsius for about 24 hours after slaughter to prevent muscle stiffness and flesh atrophy. Following this, the meat will be combined and incubated at -1 to 2°C for approximately 5 to 14 days. During the brewing process, the proteins in the muscles of beef begin to create enzymes that break down muscle fibers, resulting in a softer product.

Currently, the Phu Lam company intends to continue processing chilled meat for export. Due to the close proximity to the Chinese border, exporting to this enormous market would be quite advantageous.

Mr. Nguyen Minh Bach anticipated receiving assistance from Quang Ninh province in obtaining funding to expand the project.

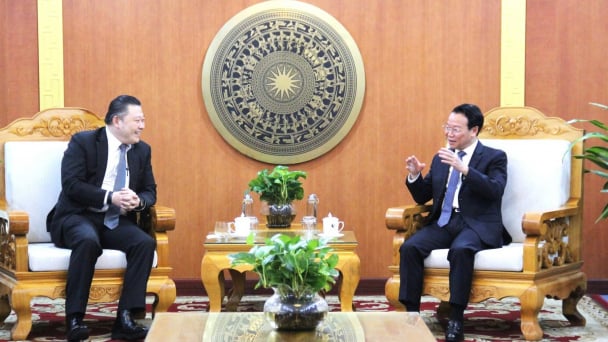

Mr. Pham Van Thanh, Vice Chairman of Quang Ninh Provincial People's Committee, stated that the beef and breeding farm of the Phu Lam enterprise has made a very positive contribution to the growth of the agricultural industry in the province, generating a chain of linkages. Connecting areas that produce grass and biomass maize for animals will provide 200 local jobs and contribute directly to the local budget on an annual basis.

According to data from the Department of Agriculture and Rural Development of Quang Ninh, the production value of the province's livestock industry will expand by 7.6 percent by the end of 2021, and the proportion of livestock in agriculture will reach 56 percent. In terms of total cattle herds in the province, all attained and surpassed the growth targets established at the start of the year. Thus, it has significantly contributed to the overall expansion of the agricultural industry.

Translated by Linh Linh

(VAN) Minister of Agriculture and Environment Do Duc Duy held a meeting with Soopakij Chearavanont, Chairman of C.P. Group, on May 15.

/2025/05/16/3800-0-nongnghiep-143756.jpg)

(VAN) Suntory PepsiCo Vietnam coordinated with the Ministry of Education and Training to implement an education program on water conservation, reaching nearly 1 million primary school students nationwide.

(VAN) Vietnam’s TH Group officially put its high-tech fresh milk processing plant into operation in the Russian Federation, marking a historic moment as the first TH true MILK cartons were produced in Russia.

(VAN) Use of high-quality broodstock and biotechnology is regarded as the most effective approach to ensuring sustainable and economically viable shrimp aquaculture ahead of climate change and the emergence of increasingly intricate disease patterns.

(VAN) Carbon farming is a form of agricultural practices that helps absorb more greenhouse gases than it emits, through smart management of soil, crops, and livestock.

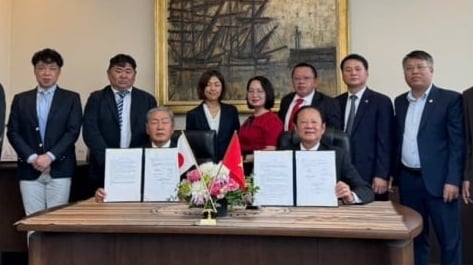

(VAN) This is a key content of the Memorandum of Understanding recently signed between the Vietnam Fisheries Society and Kunihiro Inc of Japan.

(VAN) To achieve the goal, local authorities and businesses in Kon Tum province have fully prepared the necessary conditions for the new Ngoc Linh ginseng planting season.