May 30, 2025 | 05:21 GMT +7

May 30, 2025 | 05:21 GMT +7

Hotline: 0913.378.918

May 30, 2025 | 05:21 GMT +7

Hotline: 0913.378.918

The Semi-Biofloc shrimp farming model at Viet Uc-Phu My Co., Ltd. in My Thanh Commune (Phu My District, Binh Dinh Province). Photo: V.D.T.

According to Tran Quang Nhut, Deputy Director of the Binh Dinh Province's Agricultural Extension Center, the adoption of Semi-Biofloc technology in white-leg shrimp farming is growing rapidly within the province. To date, Binh Dinh Province hosts 65 hectares of shrimp farms utilizing Semi-Biofloc technology, with Phu Cat and Phu My Districts housing the largest farms.

In 2020, Binh Dinh Province's Agricultural Extension Center implemented a scientific project titled “Research on improving intensive and semi-intensive farming techniques for commercial white-leg shrimp farming using Semi-Biofloc technology to promote sustainable development in Binh Dinh Province.” Deputy Director Tran Quang Nhut served as the project’s lead researcher.

After 23 months of research and field trials, the project was successfully reviewed and approved by the Binh Dinh Province's Science and Technology Council in mid-July 2022.

According to Deputy Director Nhut, Semi-Biofloc technology doubles shrimp productivity compared to traditional farming practices. Consequently, shrimp yields increase significantly as stocking density reaches up to 200 shrimp per square meter. Conversely, traditional farming practices allow for only 100 to 150 shrimp per square meter. Similarly, extensive farming methods have a significantly lower stocking density at only 50 to 60 shrimp per square meter. On the other hand, Semi-Biofloc technology reduces input costs by 10 to 15% compared to traditional farming due to lower expenditures on antibiotics and feed waste. The technology also reduces the use of groundwater by stabilizing water quality through microalgae.

The Semi-Biofloc technology requires shrimp farmers to equip their farms with lined ponds, coverings, water treatment systems, and aeration devices and follow a two-stage farming process. Accordingly, farmers must rear shrimp seeds for 25 to 30 days until they reach a size of 600 to 800 shrimp per kilogram. Subsequently, farmers must transfer the shrimp to grow-out ponds with a stocking density of 180 to 200 shrimp per square meter. During the farming process, farmers ferment molasses to bind feed and culture floc to supply the ponds.

Deputy Director Nhut emphasized that the Semi-Biofloc technology is more effective during off-season crops when adverse weather conditions such as rain and storms are common. This method mitigates the effects of external weather, enabling year-round farming with the potential for four harvests per year, compared to only two harvests using traditional farming practices.

Pham Xuan Phuong, a farmer in Duc Pho 1 Village, Cat Minh Commune (Phu Cat District, Binh Dinh Province), applied Semi-Biofloc technology to his 1,000-square-meter pond during the last crop. “This is a new farming method that reduces disease in shrimp and eliminates the use of antibiotics, thereby lowering production costs and increasing income compared to traditional farming practices,” Phuong shared.

Nguyen Ngoc Chau, a resident of Cat Minh Commune (Phu Cat District, Binh Dinh Province) was the first to adopt Semi-Biofloc technology in commercial shrimp farming. Photo: V.D.T.

The sudden increase in shrimp prices has encouraged farmers in high-tide areas to stock shrimp for the off-season and sell at higher prices during the year-end harvest. Semi-Biofloc technology has further reinforced this confidence.

"Semi-Biofloc shrimp farming requires only small ponds, around 1,000 square meters, for easier management. The ponds are equipped with netting systems that mitigate the effects of external weather. Ponds with surrounding nets can also block the cold winds of the northeast monsoon," said Tran Quang Nhut.

Multiple shrimp farms at the Ninh Phu aquaculture area in Ninh Hoa Town, Khanh Hoa Province, have ceased operations. However, the shrimp ponds at Ninh Phu Aquaculture Cooperative, which utilize lined-basin Semi-Biofloc technology combined with a three-stage farming process, are still in operation. Additionally, water aerators are constantly oxygenating the ponds.

Le Minh Chinh, Director of Ninh Phu Aquaculture Cooperative, is currently farming shrimp in eight ponds, each covering 1,600 square meters. The shrimp are currently 50 to 60 days old, and they will be ready for harvest in approximately 10 days. However, Director Chinh plans to extend the farming period for ponds with well-developed shrimp to harvest larger shrimp, which can fetch higher prices.

Nguyen Ngoc Chau inspecting the development of shrimp in his farm. Photo: V.D.T.

Director Le Minh Chinh shared that the cooperative consists of six members farming shrimp across a total area of approximately 10 hectares, with around 5 hectares dedicated to shrimp ponds and the remainder for water-settling ponds. Over the years, the cooperative has adopted the Semi-Biofloc technology in a three-stage process, producing 3 to 4 harvests annually with a total yield ranging from 300 to 400 tons.

According to Director Chinh, despite its age, Semi-Biofloc technology offers numerous advantages, such as purifying and stabilizing the water environment through the use of microalgae. Biofloc consists of heterotrophic bacteria, algae, and organic matter that clean the water, provide a nutritious food source for the shrimp, and inhibit the growth of harmful microorganisms. This technology helps boost shrimp's growth, controls diseases, and ensures food safety.

The three-stage farming process further reduces feed and electricity costs in addition to promoting disease prevention in the early farming stages. In the event of a disease outbreak, farmers can terminate the process prematurely to avoid significant losses.

Director Chinh explained the three-stage shrimp farming process as follows: During the first stage, farmers rear shrimp in a tank of more than 100 square meters with a stocking density of 250,000 to 500,000 seeds. The shrimp will reach a size of 1,000 to 1,200 shrimp per kilogram after approximately 30 days. Subsequently, farmers will proceed to the second stage.

In the second stage, farmers transfer the shrimp to outdoor ponds and utilize Semi-Biofloc technology for approximately 25 days. At this point, the shrimp will reach a size of 200 to 250 shrimp per kilogram with a density of 500 shrimp per square meter before reaching the third stage.

In the third stage, the stocking density is halved to 250 to 300 shrimp per square meter. Farmers will rear the shrimp for an additional 90 days until they reach an average size of 50 shrimp per kilogram. Each pond, which spans 1,600 square meters, yields an average of 6 to 7 tons per crop, with the highest yield recorded at 8 tons per crop.

With a stocking density of 300 shrimp per square meter, Chinh reported that after 60 days of farming, the shrimp can reach a size of 100 shrimp per kilogram. In exchange, farmers will need to invest a total of 50 to 60 thousand VND per kilogram. “At the moment, the cooperative's Semi-Biofloc farming model, combined with the three-stage process, has allowed our members to achieve a success rate between 70 and 80%,” Director Chinh reported.

Nguyen Van Tien, an experienced shrimp farmer in Kim Giao Thien Village, Hoai Hai Commune (Hoai Nhon Town, Binh Dinh Province), remarked that despite the risk of disease outbreak in the region due to unpredictable weather conditions, the shrimp in his Semi-Biofloc ponds continue to exhibit exceptional and disease-free growth. Accordingly, he has received detailed instructions on water sourcing, water treatment, and biofloc cultivation.

“In recent years, the Semi-Biofloc shrimp farming model in Binh Dinh Province has produced an average yield of 10 tons per hectare, representing an increase of 2 to 4 tons per hectare compared to traditional farming practices. Semi-Biofloc technology reduces water pollution through the biofloc system and limits the use of chemicals and antibiotics, thereby lowering input costs and increasing profits for shrimp farmers,” commented Deputy Director Tran Quang Nhut.

Translated by Nguyen Hai Long

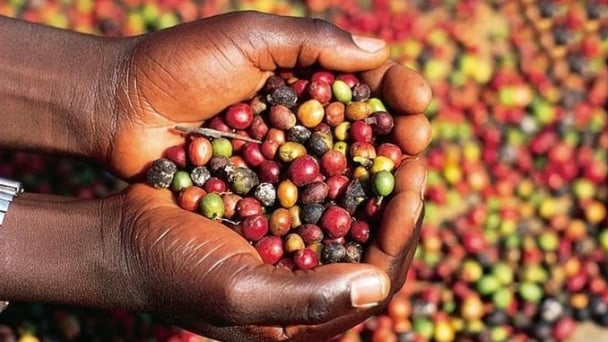

(VAN) Coffee prices on May 29, 2025, are fluctuating. The domestic coffee market declined, dropping by VND 2,200, trading at VND 119,700 – VND 120,000/kg.

(VAN) Pepper prices on May 29, 2025 declined sharply. Domestic pepper prices in Vietnam remain stable, Trading at VND 147,000 to VND 148,000/kg.

(VAN) Rubber prices on May 28, 2025 are maintaining an upward trend. Domestic latex prices remain stable, trading in the range of VND 397 to VND 462/TSC.

(VAN) Coffee prices on May 28, 2025, show mixed movements. Domestically, prices dropped sharply by VND 1,600, trading at VND 121,700 – VND 122,200/kg.

(VAN) Pepper prices on May 28, 2025, remained unchanged globally. Domestic pepper prices have increased by VND 1,500, trading at VND 147,000 – VND 148,000/kg.

(VAN) Rice prices on May 27, 2025, show no new changes for both paddy and milled rice. Meanwhile, Vietnam’s export rice prices continue to remain flat.

(VAN) Pepper prices on May 27, 2025, recorded a slight increase in Indonesia, while domestic prices remain stable, trading at VND 146,000 to VND 147,000/kg.