May 16, 2025 | 10:46 GMT +7

May 16, 2025 | 10:46 GMT +7

Hotline: 0913.378.918

May 16, 2025 | 10:46 GMT +7

Hotline: 0913.378.918

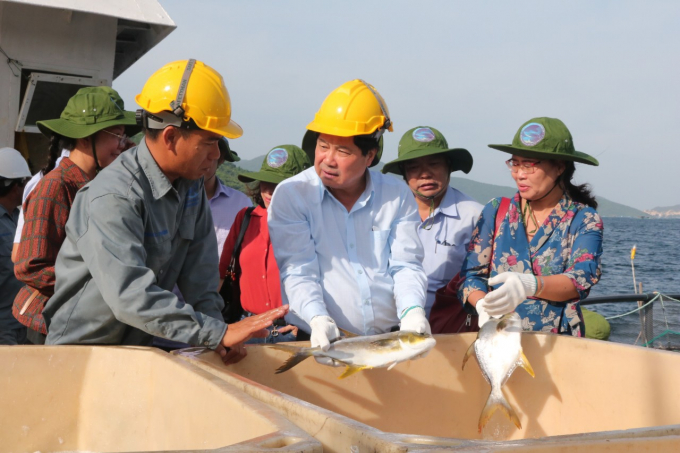

Marine farm belonging to Institute I on Van Phong bay, Khanh Hoa province. Photo: KS.

We had the chance to visit the enclosed circulating yellowfin specialty farm following Norwegian technology belonging to the High-tech Marine Breeding Center on Van Phong Bay, Van Ninh District (Khanh Hoa) of the Institute of Aquaculture Research I (Institute I for short).

The farm was established in mid-2013 with an area of about 10 hectares of sea surface. In which, there are 20 HDPE round cages, each cage has a circumference of 60m, mainly for commercial yellowfin pompano. There are also 22 square cages with the size of 5x5x5m using HDPE materials to raise broodstock and fingerlings.

The fish farming process here does not rely on antibiotics at all, it uses 100% industrial feed, so loss rate is low. Specifically, the survival rate of fish usually reaches 76-84% from the time of stocking to the end of the culture period lasting 8-10 months. This is one of the units pioneering in the country's first industrial-oriented farming of yellowfin pompano that has officially been recognized as meeting VietGAP standards.

Yellowfin pompano farm using machines to feed. Photo: KS.

Mr. Pham Duc Phuong, Director of the Center for High-Tech Aquaculture, said that the Center currently has a total of 15 staffs, 9 of which are directly involved with the farm to raise marine fish. All of the staffs have been recruited and trained on labor safety regulations, biosafety, first aid and techniques in marine aquaculture.

In addition, to serve the process of marine farming, the farm is equipped with a dedicated working vessel. This vessel is responsible for both transporting goods and labor, performing heavy work such as loading and unloading goods, lifting nets and harvesting instead of manual labor thanks to the large crane installed on the front of the deck.

Since 2018, the farm has operated stably with an output of about 200 tons/crop, fish weighing within the range of 500-1,000 grams/fish. Currently, the production of commercial fish farmed here, in addition to domestic consumption, is also exported to the US and Middle East countries; with selling price ranging from 110-150,000 VND/kg, netting 20-30% profit.

The farm belonging to the Center for High-Tech Aquaculture specializes in raising yellowfin pompano. Photo: LK.

According to Institute I, currently the technological processes applied on the farm have been mastered by Institute I and successfully applied in practice from seed production, commercial farming, feed management, fish feeding, fish disease prevention and treatment to harvesting and product preservation, traceability...

Notably, a few technological processes have been recognized for its technical advancedness such as the production technology of yellowfin pompano; process of commercial farming of yellowfin pompano in cages on an industrial scale, the process of environment monitoring, disease prevention and control of yellowfin pompano raised in sea cages.

In particular, Institute I has also mastered the technology of designing and installing HDPE cages following Norwegian technology with localized cage materials, reducing costs by over 50% compared to imported cages. The system of cages and anchors is designed to withstand level 11 hurricanes. However, in reality, it can withstand a strong hurricane of up to level 12 and gust level 15 similar to Hurricane No. 12 (Damrey) that occured at the end of 2017 and passed through the cage area.

Deputy Minister of Agriculture and Rural Development Le Quoc Doanh visiting the marine farm of Institute I. Photo: KS.

In October 2020, Deputy Minister of Agriculture and Rural Development Le Quoc Doanh also visited this marine fish farm and praised Institute I highly for pioneering marine fish farming utilizing Norwegian-style cages. According to Deputy Minister Le Quoc Doanh, Institute I has not only mastered the technological process from producing yellowfin pompano, producing industrial feed following the cooperation formula between Institute I and De Heus Company (Netherlands), but also biosafety commercial farming; application of Norwegian-style cage technology suitable to actual practical conditions in Vietnam.

Therefore, the Deputy Minister directed Institute I to continue researching and perfecting the marine farming process for many other targets, as well as continuing to research and improve cage technology to suit the conditions of each farming area... From there, promotethe transfer of farming technology to businesses and farmers, in order to serve the marine farming strategy in the future.

An industrial-scale barramundi farming area on Van Phong Bay belonging to Australis Vietnam Seafood Co., Ltd. Photo: KS.

In addition to Institute I, on Van Phong Bay, Australis Vietnam Seafood Co., Ltd., with 100% foreign capital from the United States, was established in Khanh Hoa province over 12 years ago, and is currently raising barramundi specialties on an industrial scale.

The Company's barramundi is grown in seawater areas in large Norwegian-style cages with a high degree of automation. Specifically, the fish is fed using an automatic system, the robotic camera monitors the fish underwater while managing the feeding accurately, ensuring the hygiene of the marine environment...

The company is reported to currently have 3 farming areas in Van Phong Bay, each area has 14 cages and each cage can harvest 250-300 tons of fish per culture cycle. The company typically harvests fish five to seven days a week and processes seabass products into frozen fish fillets to serve the global market. Company products are sold under the brand names Better Fish and Clean Harvest.

By now, the Company has become the largest producer of barramundi in the world with processing facilities in various locations in Khanh Hoa province.

At a workshop on sustainable marine aquaculture development held in Phu Yen at the end of 2020, a representative from Australis Vietnam Seafood Co., Ltd., said that the company has spent 3 years researching 30 aquatic species globally and finally selected seabass as the most suitable species of marine culture in Vietnam. Because barramundi has a good feed conversion ratio, year-round growth and excellent meat quality, it can replace other tropical seafood such as grouper or sea bass that are being over-exploited.

Sharing on the effective methods for marine farming, a representative from this company said that the area for marine aquaculture should be prioritized and separated from industrial development. Additionally, there are 4 factors to be ensured including seed source, diagnosis and vaccine, ensuring a source of feed for broodstock and feed for farmed fish during marine culture. This is a sustainable farming factor that the company focuses on in the marine farming process and it is also a factor that has been certified by world's leading organizations.

Processing seabass at Australis Vietnam Seafood Co., Ltd. Photo: KS.

In addition to the aforementioned factors, the creation, innovation and branding are also focused, prioritized by Australis Vietnam Seafood Co., Ltd., in their development strategy. Therefore, the company's product supply partners are the world's leading chains or supermarkets, including the US.

The Company believes that, in order to realize the output target in the field of marine farming and export, Vietnam needs to cooperate and activate the aquaculture ecosystem. In addition to this, it is necessary to apply new technologies, such as Norwegian technology, to solve the challenge of scaling up production, as well as to withstand extreme weather conditions.

However, this plan requires a very large capital investment, so there should be sustainable conditions for investors, such as the term of land lease and the farming area needs to be protected against environmental impacts, as well as appropriate policies related to biosafety, food additives, feed additives...

Step by step towards industrial scale marine farming

According to Mr. Huynh Kim Khanh, Director of Khanh Hoa Agricultural Extension Center, industrial-scale marine farming such as those of Institute I and Australis Vietnam Seafood Co., Ltd. is very suitable for businesses with large financial resources.

As for farmers, due to their qualifications and finance, investment in marine aquaculture is limited, so they cannot "jump" directly into farming on an industrial scale. Therefore, Khanh Hoa Agricultural Extension Center is supporting farmers in a way that is suitable for household size, without using cumbersome machinery. However, when the farmers' marine farming foundation is solid, with accumulated capital, they will move to industrial scale farming to be more efficient.

Also according to Mr. Khanh, in addition to sea fish, lobster is a specialty of Khanh Hoa province that farmers focus on raising. However, the characteristics of lobster is that they need to be raised in square cages. Therefore, in order to help farmers access the technology of HDPE square cages that can withstand the waves replacing wooden cages, we will build this model with the province's agricultural extension funds in the near future.

Translated by Nguyen Hai Long

(VAN) Vietnam’s TH Group officially put its high-tech fresh milk processing plant into operation in the Russian Federation, marking a historic moment as the first TH true MILK cartons were produced in Russia.

(VAN) Use of high-quality broodstock and biotechnology is regarded as the most effective approach to ensuring sustainable and economically viable shrimp aquaculture ahead of climate change and the emergence of increasingly intricate disease patterns.

(VAN) Carbon farming is a form of agricultural practices that helps absorb more greenhouse gases than it emits, through smart management of soil, crops, and livestock.

(VAN) This is a key content of the Memorandum of Understanding recently signed between the Vietnam Fisheries Society and Kunihiro Inc of Japan.

(VAN) To achieve the goal, local authorities and businesses in Kon Tum province have fully prepared the necessary conditions for the new Ngoc Linh ginseng planting season.

(VAN) Jiangsu province is gearing up to host training programs in Phnom Penh, the capital of Cambodia, this year to establish the Fish and Rice Corridor.

(VAN) Le Hoang Minh, representing Vinamilk, shared the company's experience in energy saving and green energy transition for production at a workshop held during the P4G Summit.