June 2, 2025 | 13:58 GMT +7

June 2, 2025 | 13:58 GMT +7

Hotline: 0913.378.918

June 2, 2025 | 13:58 GMT +7

Hotline: 0913.378.918

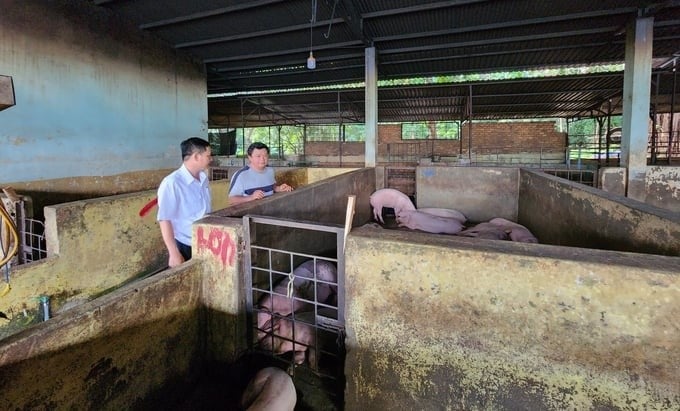

The slaughter facility of Mr. Pham Quoc Thuong, owner of Bui Thi Nhung business household (Ea Tu commune, Buon Ma Thuot city, Dak Lak), was invested in for more than VND 3 billion but only slaughters about 30 pigs every night. Photo: Minh Quy.

Mr. Pham Quoc Thuong, owner of Bui Thi Nhung business household (Ea Tu commune, Buon Ma Thuot city, Dak Lak), said that his family has been slaughtering since 1998. At the end of 2020, he spent more than VND 3 billion to build a pig and chicken slaughter facility in Ea Tul commune. The facility’s operating capacity on the license is more than 100 pigs and 1,000 chickens each day.

Despite investing billions, the facility now only slaughters about 30 pigs and 10 chickens each night; even some nights there are no goods. Only C.P. Vietnam Livestock Corporation-Dak Lak Branch registers for slaughtering at the facility while surrounding households self-slaughter at home.

“The facility invested in a wastewater treatment system through five filter tanks and signed with an environmental company to collect trash daily. Despite the large investment, each pig slaughtered at the facility is charged VND 30,000–40,000. With a small quantity like this, the facility’s revenue is not enough to cover expenses,” Mr. Thuong worried.

Similarly, Ms. Tran Thi Duong, owner of the Ea Phe concentrated cattle slaughter facility in Krong Pac district, also invested more than VND 3 billion to build a modern slaughterhouse to meet new rural criteria. However, on average, the facility now slaughters about 60 pigs every day, while the facility's capacity should be over 200 pigs.

“The investment in the slaughterhouse is large and the number of animals slaughtered at the slaughterhouse is small, but we still have to maintain it to let slaughtering households in the surrounding areas see how effective concentrated slaughter is for food safety. Particularly, all environmental criteria and regulations of functional agencies are guaranteed at the facility. Thereby, the amount of meat that the facility supplies is guaranteed to be safe," said Ms. Duong.

Some slaughter facilities in Dak Lak were invested in for billions of dongs but are operating moderately. Photo: Quang Yen.

According to the facility owner, there are many C-rated facilities around that are still operating, while according to regulations, they are not allowed to operate. In addition, many households also self-slaughter and sell meat at home. The functional agencies have not yet been able to manage this problem.

When investing in a qualified slaughterhouse and contributing to a criterion in the locality’s new rural construction program, Ms. Duong’s family wishes to receive support from the local authority. In particular, currently, the slaughtering price at her facility is only VND 30,000/head, which is too low compared to that of facilities invested decades ago.

The current price at other facilities ranges from VND 40,000 to VND 45,000/head. This revenue level is too low, not enough to cover expenses of hiring workers, electricity, and water, as well as asset depreciation. Therefore, the facility also proposed that the functional agencies allow the unit to raise the price to be equal to other facilities.

The slaughterhouse that DAKFARM Food Production and Processing Co., Ltd. invested in in 1999 is now degraded. The company wants to relocate it but cannot. Photo: Minh Quy.

In addition to investment establishments that operate moderately, many businesses with slaughter sites located in residential areas want to relocate them to other places but cannot. Mr. Nguyen Anh Tuan, Deputy Director of DAKFARM Food Production and Processing Co., Ltd., said that the business has twice submitted applications to the functional agencies to rent land to relocate the company's slaughterhouse and build a modern concentrated slaughter facility but failed.

According to Mr. Tuan, in 1999, the family was mobilized and guided by functional agencies to build a concentrated cattle slaughter facility in Tan Loi ward, Buon Ma Thuot city. However, in the process of urbanization, the company's facility is located in a residential area, so it must be relocated. Besides, the facility has been invested in and operated for decades, so it has now degraded and is no longer safe.

“Because the facility is located in a residential area and is not safe, many times the company wants to upgrade and repair it to ensure safety. However, because we do not know when the city requires relocation, we do not dare make repairs and still operate moderately," said Mr. Tuan.

Therefore, to meet the unit's need for concentrated animal slaughter, the business has asked the Buon Ma Thuat City People's Committee to lease 10,000 m2 of land that has been planned to build a concentrated animal slaughter facility. When land is allocated, the company will build a slaughterhouse with advanced and modern technology.

DAKFARM Company's facility is degraded, but the business does not dare upgrade or repair it. Photo: Minh Quy.

"The unit has twice visited places where the city has planned for concentrated livestock and slaughter areas. However, due to the policy changes, the livestock area and slaughter area now must be separate, while the city has not had a specific plan for which areas to be invested in for slaughtering. Therefore, the business hopes that the local authority will soon plan the slaughter area as well as have supporting policies," said the Deputy Director of DAKFARM Company.

According to Mr. Hoang Anh Dung, Head of Buon Ma Thuot Animal Husbandry and Veterinary Station, before 1999, Buon Ma Thuot City had more than 100 slaughter points. After that, functional agencies mobilized and gathered at each stage, and up until now, there have been seven concentrated slaughter points left. Currently, the station only has the function of management and quarantine at slaughterhouses. As for markets, the station is not allowed.

The most difficult thing in slaughter management is the lack of land funds to build concentrated slaughter facilities. The station has disseminated and mobilized a case to build a modern slaughterhouse and, at the same time, coordinated with businesses to find land in planned areas, but still did not meet QCVN 01-150:2017/BNNPTNT.

Translated by Huyen Vu Thu

(VAN) Several scientists and farmers are experimenting with soil treatment in some key durian-growing regions such as Cai Lay (Tien Giang), Dak Song, Gia Nghia, and Dak R’lap (Dak Nong).

/2025/05/25/4127-3-073637_820.jpg)

(VAN) Thanks to the promotion from an FAO-implemented project, vegetable production in greenhouses in Moc Chau has seen strong development, from 1.5 hectares in 2021 to nearly 50 hectares in 2024.

(VAN) FAO has recently supported USD 140,000 to implement the project 'Risk mitigation human-animal interface risks through disease control initiatives in pig farming.'

(VAN) The People's Committee of Tra Vinh province has approved an adjustment to the investment policy for the Green Hydrogen Plant project, increasing its area to approximately 52.76 hectares.

![Reducing emissions from rice fields: [2] Farmers’ commitment to the soil](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/05/05/dsc08881jpg-nongnghiep-140632.jpg)

(VAN) Clean rice cultivation model in Thuong Tan commune, Bac Tan Uyen district, is assisting local residents in achieving sustainable agriculture by substantially reducing costs, increasing productivity, and protecting the environment.

(VAN) At the conference to disseminate Resolution No. 68, AgriS introduced its digital agricultural ecosystem and reaffirmed its commitment to accompanying the Government in promoting private sector development and sustainable agriculture.

(VAN) 'Blue Ocean - Blue Foods' initiative is designed to restore marine ecosystems and establish sustainable livelihoods for local communities by cultivating a minimum of 1,000 hectares of cottonii seaweed in the first three years.