May 16, 2025 | 09:48 GMT +7

May 16, 2025 | 09:48 GMT +7

Hotline: 0913.378.918

May 16, 2025 | 09:48 GMT +7

Hotline: 0913.378.918

Ben Tre province's Department of Science and Technology recently introduced a processing technology and equipment system for processing and preserving fresh pomelos to support domestic consumption and export. The project was spearheaded by the Sub-Institute of Agricultural Engineering and Post-Harvest Technology under the Institute of Agricultural Engineering and Post-Harvest Technology - Ministry of Agriculture and Rural Development.

Green-skinned pomelo is one of Ben Tre province's key fruit products. Photo: Minh Dam.

According to MSc. Nguyen Vinh Phuc, Project leader, the post-harvest technological procedure for green-skinned pomelos, from farm to warehouse, consists of several sequential steps: sorting, washing, air-drying, wax coating, shrink wrapping, and boxing.

Following a preliminary sorting and selection stage, pomelos are submerged in a chlorine-infused aerated tank tank for approximately two to five minutes. Subsequently, they are delivered on a conveyor belt to an air-drying system. Next, the fruits are moved to a roller conveyor for polishing to ensure a dry surface.

During the wax coating stage, a thin layer of 20% carnauba wax is applied over the pomelo's surface, at a rate of 0.3 to 0.5 milliliters per fruit, or 0.5 grams per 25 square centimers. This layer of coating, made from edible natural wax, inhibits the fruit's respiration process, creates a glossy appearance, and preserves the fruit's green color.

This wax coating extends the pomelo's shelf life, reduces spoilage rates, thereby enabling transport to distant markets. This stage typically requires five to ten minutes for the wax to adequately dry; a fan can be used to accelerate the process. Subsequently, each fruit is wrapped in polyolefin shrink film and placed in cardboard boxes to facilitate prolonged preservation and convenient shipping, mitigating potential damage from impacts. Ultimately, the pomelos are stored at a controlled temperature of 10 degrees Celsius to maintain optimal quality.

According to Ms. Truong Trinh Truong Vinh, Deputy Director of Ben Tre province's Department of Science and Technology, the project has successfully established a technological process for the preliminary processing, processing, and preservation of Ben Tre green-skinned pomelos. Consequently, this achievement helps to preserve pomelos at an optimal quality, extend storage time, and reduce spoilage rates to below 15%.

Ms. Truong Trinh Truong Vinh further noted that Vietnamese green-skinned pomelos have been approved for official export to various demanding markets around the world, including the United States, Europe, and Australia. The export of Vietnamese pomelos to foreign markets requires varying shipping durations. Notably, air exports to distant and high-value markets typically require a shipping duration of one to two days. However, air freight charges are substantial, occasionally accounting for up to 50% of the total cost. As a result, Vietnamese green-skinned pomelos face considerable difficulty in competing with fruits from other exporters.

On the other hand, sea exports significantly reduce costs but extend shipping durations, which can last up to three to four weeks. Consequently, suitable preservation technological solutions can meet the demands of extended shipping durations.

Pomelo sorting prior to the washing process. Photo: Minh Dam.

Ms. Ly Thi Ngoc Minh, Director of Green Power Company located in Hamlet 2, Son Phu, Giong Trom, Ben Tre, commented: "Green-skinned pomelo is one of our company's key products. Last year, we exported over 10,000 tons of this fruit. This research project possesses significant potential for practical application, particularly in extending the shelf life of pomelos. Moreover, its application is essential given the extended sea shipping duration to Europe, which recently increased from 35 to 45 days. The same is also true for exports to the US market; this preservation solution will be highly effective, and can be replicated by other businesses. In addition, it assists in preserving pomelos during high-yield crop cycle with low market consumption."

Green-skinned pomelo is one of Ben Tre province's key fruit products, with a total production area of 9,400 hectares, accounting for 34% of the province's total fruit tree production area. Pomelo is among the eight local products certified for the protection of geographical indication and perpetual industrial property rights in the domestic market. Additionally, the province is currently registering for the protection of Ben Tre green-skinned pomelo geographical indication in international markets.

The successful research into the technological process and equipment system for processing and preserving fresh pomelos in Ben Tre province has contributed to enhancing the quality and competitiveness of this local key agricultural product. Additionally, the research serves as a driving force for the development of green-skinned pomelos in the Mekong Delta region.

Translated by Nguyen Hai Long

(VAN) Vietnam’s TH Group officially put its high-tech fresh milk processing plant into operation in the Russian Federation, marking a historic moment as the first TH true MILK cartons were produced in Russia.

(VAN) Use of high-quality broodstock and biotechnology is regarded as the most effective approach to ensuring sustainable and economically viable shrimp aquaculture ahead of climate change and the emergence of increasingly intricate disease patterns.

(VAN) Carbon farming is a form of agricultural practices that helps absorb more greenhouse gases than it emits, through smart management of soil, crops, and livestock.

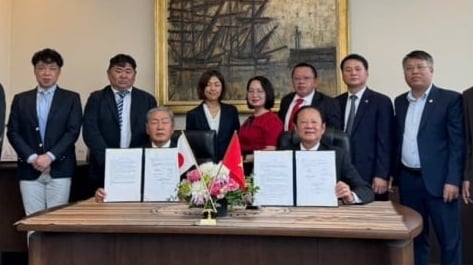

(VAN) This is a key content of the Memorandum of Understanding recently signed between the Vietnam Fisheries Society and Kunihiro Inc of Japan.

(VAN) To achieve the goal, local authorities and businesses in Kon Tum province have fully prepared the necessary conditions for the new Ngoc Linh ginseng planting season.

(VAN) Jiangsu province is gearing up to host training programs in Phnom Penh, the capital of Cambodia, this year to establish the Fish and Rice Corridor.

(VAN) Le Hoang Minh, representing Vinamilk, shared the company's experience in energy saving and green energy transition for production at a workshop held during the P4G Summit.