June 20, 2025 | 23:39 GMT +7

June 20, 2025 | 23:39 GMT +7

Hotline: 0913.378.918

June 20, 2025 | 23:39 GMT +7

Hotline: 0913.378.918

Bac Lieu is developing high-tech shrimp farming models divided into 2-3 phases and adapting to climate change. Photo: Le Hoang Vu.

Bac Lieu is known as the "hub" of shrimp farming in Vietnam. The province prioritizes shrimp for domestic and foreign markets, therefore contributing to local economic growth.

When Bac Lieu is recognized as the industrial hub of the shrimp business, shrimp farming in the province has achieved enormous strides, and several innovative techniques have been implemented to fight extreme weather, alleviate risks caused by epidemics and illness, and increase economic efficiency. The model was replicated and the appliance was promoted to enhance the local shrimp business.

Statistics from the Bac Lieu Department of Agriculture and Rural Development indicate that the total shrimp farming area of the province is 145,000 hectares, with 1,800 hectares devoted to super-intensive shrimp farming, 185,22 hectares devoted to farming water surface area, and 1,600 ponds/lakes for shrimp farming. The super-intensive vannamei farming model in circular floating ponds leads in survival rates between 70 and 90%. By controlling the pumping of fresh water directly from rivers and canals as well as pumping discharge to the environment, the model contributes to environmental protection by preventing the spread of disease.

High-tech shrimp farming is 3 times more profitable than traditional shrimp farming outside of earthen ponds.

With this farming approach, super-intensive vannamei shrimp yields from 50 to 55 tons per hectare, generating a profit of around 2 billion VND per hectare, which is three times more than traditional shrimp farming in earthen ponds.

Mr. Hoang Van Hai, a resident of Bien Tay A village, Vinh Trach Dong commune, Bac Lieu city, has years of conventional shrimp farming expertise. Two years later, he intended to transform into a super-intensive model by adopting advanced technologies. On 3 hectares of shrimp-farming land, he invested in the construction of two high-tech shrimp-farming ponds and one for treated discharged water. Each pond has an average width of 1,400 m2 and uses modern farming techniques in two to three stages, depending on the season, to promote rapid shrimp growth and prevent disease. Therefore, many prior shrimp cultivations were always successful and 30-40% more profitable than traditional farming methods.

High-tech shrimp farming necessitates a higher initial investment but has several advantages, such as preventing contamination of farming water sources and disease transmission, saving electronic and water resources, and simplifying all technical shrimp farming processes.

The super-intensive vannamei farming model in circular floating ponds leads to survival rates between 70 and 90%. Photo: Le Hoang Vu.

Particularly, super-intensive shrimp farming reduces the risk of shrimp dying prematurely 25-30 days after stocking (due to AHDNP acute hepatopancreatic necrosis disease), allowing an average of three to four shrimp harvests per year to be stocked. This model avoids the need for antibiotics and pesticides in shrimp farming, has little impact on the environment, produces a safe environment for shrimp growth, and reduces disease. It has a high stocking density of 150 to 300 fish per square meter and a short harvesting period of 2.5 to 3.5 months.

Mr. Hai said that he farmed his last shrimp harvest in two ponds, utilizing all of GrowMax's feed items to assist the shrimp to develop rapidly and with less disease, so the loss per shrimp head seemed minimal. After subtracting expenses, he gathered almost 15 tons of shrimp and earned VND 1 billion.

Mr. Tran Tuan Em has eight shrimp ponds equipped with advanced technology and water filtration and circulation system provided by GrowMax Company. The shrimp develop well as a result of feeding GrowMax feeds, and the watercolor stays fresh due to the water filtration circulation system, which saves him a substantial amount of money in terms of labor and electricity. The adoption, according to him, increased production by 30-40% compared to conventional shrimp farming in earthen ponds.

GrowMax's feeds assist the shrimp to develop rapidly and with less disease, so the loss per shrimp head seemed minimal. Photo: Le Hoang Vu.

Farmers are more confident, shrimp are less sick, and productivity is high as a result of innovative shrimp farming utilizing cutting-edge technology to adapt to climate change. Mr. Tran Tuan Em's novel farming strategy produces eight to nine batches of shrimp every year, with an average output of sixty to seventy tons, earning billions of dollars in revenue. Particularly during the shrimp farming season, he feeds the shrimp industrial feed from GrowMax Company, based on a feed coefficient of 1.3 (on average, 1.3 kg of feed yields 1 kg of commercial shrimp).

The price of shrimp is now favorable. Mr. Tran Tuan Em grows shrimp with a weight of 25-26 shrimp/kg for harvesting; the production is anticipated to be over 2.6 tons of shrimp/500m2 pond; the selling price per kilogram is VND 200,000; and after subtracting all feasible expenditures, Mr. Tran's profit margin exceeds 40 percent.

High-tech shrimp farming requires a high investment cost at the beginning thus bringing many good things later on such as fighting pollution of water sources raised in lakes, shrimps growing quickly, and there are few diseases. Photo: Le Hoang Vu.

Mr. Cao Thanh Van, Chairman of the Board of Directors of Artemia Vinh Chau - Bac Lieu Cooperative in Vinh Trach Dong Commune, Bac Lieu City (Bac Lieu), stated that the cooperative was established in 2003 on 11ha of land allocated by the government for 18 cooperative members to invest in the development of Artemia and shrimp farming. Since roughly three years ago, the cooperative has invested daringly in a high-tech shrimp farming model with a 5,000-square-meter area connected with climate change adaptation.

This year shrimp prices are quite stable which excites high-tech shrimp farmers in Bac Lieu. Photo: Le Hoang Vu.

Building 1 hectare of super-intensive vannamei shrimp costs around VND 3 billion for a net house to cover the shrimp pond, tarpaulins to line the pond's bottom, a buoy system, bottom oxygen, feed, aquatic medicine, and seedlings. During the shrimp farming process, all feeding is fully automated, allowing the shrimp to eat continually and reducing the amount of food that lingers in the water for a prolonged period of time and pollutes the pond bottom... In comparison to intensive shrimp farming in earthen ponds, this method results in a 2-3-fold increase in productivity.

Translated by Linh Linh

![Turning wind and rain into action: [10] Advancing accessible climate services for farmers](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/linhnhp/2025/06/20/1911-z6704423696987_15fd32ffc26d590d204d520c9dac6786-nongnghiep-161854.jpg)

(VAN) Not only does it help farmers 'avoid droughts and rains,' the development of agricultural climate services also enhances their ability to proactively adapt to a rapidly changing climate.

(VAN) With international assistance, the harvesting of sargassum seaweed in Quang Ngai has become increasingly regulated, thereby safeguarding marine life and ensuring the stability of coastal communities' livelihoods.

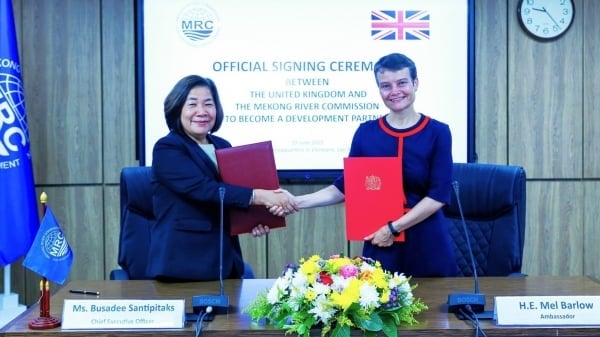

(VAN) On June 19, the United Kingdom officially became a Development Partner of the Mekong River Commission.

(VAN) Biodiversity is being threatened by traditional remedies made from wildlife. Traditional medicine and humans must change to live in harmony with nature.

(VAN) Agrifood investment and finance solutions for people and the planet.

(VAN) Microplastic contamination has become pervasive in seafood, posing unprecedented challenges for food safety and marine ecosystems.

(VAN) Proactively using vaccines, combined with transport control and enhanced surveillance, is the only viable path toward biosecure and sustainable livestock production in Vietnam.