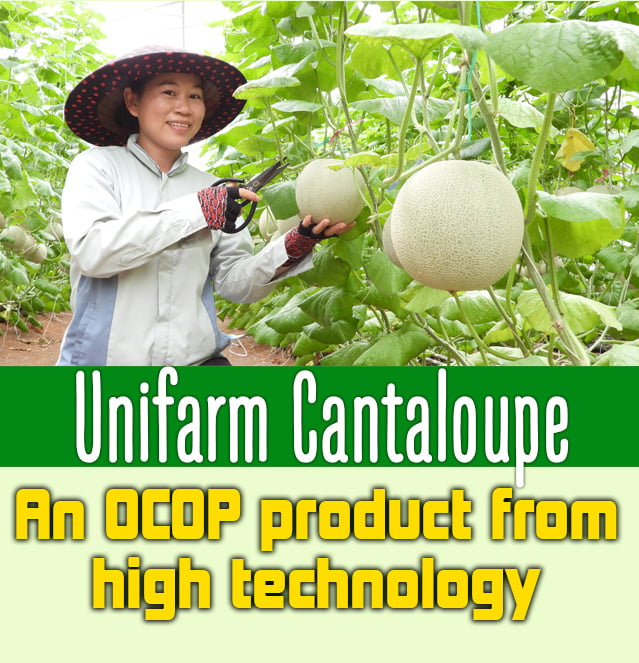

With the application of high technology to production, Unifarm's cantaloupe product always attains high and stable quality. Thanks to that, Unifarm Cantaloupe was present in most major retail systems in Vietnam and exported abroad. Unifarm Cantaloupe has also been certified with a 4-star OCOP.

Previously, when Vietnamese people began to enjoy cantaloupes, most cantaloupes on the market were imported, mainly from China. Realizing that the tropical climate in Vietnam is very suitable for growing cantaloupe, which is a type of melon with a short cultivation time, high economic value, and increasing consumption demand, many farms in Vietnam started growing cantaloupe about 10 years ago.

U&I Agriculture Joint Stock Company (Unifarm) is one of the businesses that soon started producing cantaloupe. In particular, from the beginning, Unifarm has invested in high-tech cantaloupe growing according to Israeli technology at An Thai High-Tech Agriculture Park in An Thai commune, Phu Giao district, Binh Duong province. This is the first model of growing cantaloupe with the application of Israeli technology on a large scale in Vietnam.

With Israeli technology, Unifarm's cantaloupe-growing greenhouse has the ability to diffuse light, allowing crops to receive even light distribution during the day. In addition, the greenhouse is used to provide crops with a suitable environment against adverse conditions such as wind, rain, radiation, and heat and to limit harmful insects and diseases.

To reduce water loss, Unifarm's greenhouse applies drip irrigation technology. This is the most effective and economical method in all of today’s irrigation systems. The amount of water saved by using this method can be up to 50% compared to the traditional spray irrigation method. In principle, water is directed at an appropriate flow rate to directly irrigate the root of the tree, minimizing water loss when penetrating into the soil and evaporation in the air when spraying. Water is led along a specialized pipe, with the same distance from the pipe to each tree root. The amount of irrigation water is just enough to meet the growth needs of each tree.

In order to optimize irrigation efficiency, Unifarm's drip irrigation technology is managed by a professional Israeli irrigation software and control system that can be controlled remotely via the internet, smartphone software for automatic watering and fertilization, EC and pH testing, irrigation water treatment, greenhouse ventilation, display, and troubleshooting. This technology helps accurately control the amount of irrigation water and nutrients according to the crop’s needs, reduce labor costs, and store data on fertilizer logs to ensure traceability when needed.

An important highlight in cantaloupe production at Unifarm is that the cantaloupe plants are grown semi-hydroponically on the growing medium made from coconut coir. Coconut coir is very available in Vietnam and cheap thanks to large coconut production. The advantage of coconut coir is that it is an inert material (which does not contain any substance except fiber), so producers can easily control the nutritional content of the plant. In particular, this type of growing medium easily absorbs organic and inorganic nutrients and biological preparations that increase beneficial microorganisms. This growing medium brings outstanding efficiency in terms of productivity, quality, and cost savings because it can be used for many years compared to other growing medium materials.

For cantaloupe pest prevention and control, Unifarm has applied the integrated pest management (IPM) method to contribute to improving product quality. Accordingly, in Unifarm's greenhouse area, every few meters, a colorful, sticky trap plate spread with glue is placed to trap insects. At the end of the harvest crop, the cantaloupe roots are removed, and the soil is sprayed with water and wrapped in nylon for about two weeks before being planted in the new crop. Evaporation and radiation in the greenhouse cause soil temperatures to reach 70 degrees, killing pests incubating in the soil.

In addition to technology, Unifarm also pays attention to biological solutions in production. The company's farm is using honey bees to pollinate plants. In the process of collecting pollen and honey, bees help crops pollinate and increase the plant’s fruiting ability. Thanks to that, the farm reduces input costs in cantaloupe farming and increases economic efficiency.

With such technologies, Unifarm's method of growing cantaloupe brings superior results compared to conventional cultivation methods. The company can grow cantaloupe all year round (3–4 crops/year), while many other farms can only grow 1 crop/year. Unifarm's cantaloupe yield reaches up to 100 tons/ha/year, while farms with conventional cultivation only reach about 15 tons/ha/year.

High-tech production has helped Unifarm's cantaloupe product always achieve stability in quality and food safety. According to consumers’ perceptions, Unifarm Cantaloupe is crispy, cool, fragrant, and sweet and contains many nutrients that are good for health.

Unifarm is currently producing two cantaloupe varieties, including Unisweet long cantaloupe and Dutch round cantaloupe. Unisweet long cantaloupe has an oval shape, green skin, and orange flesh. The fruit, when harvested, weighs 1.5–3 kg/fruit, with crispy and sweet flesh. The Dutch round cantaloupe has round fruit, yellow skin, and green flesh. The fruit weight when harvested is 1.4 kg/fruit, with yellow skin and thick, green, crispy, sweet flesh. In particular, the sweetness of the cantaloupe produced by Unifarm is at an excellent level (Unisweet long cantaloupe has a sweetness of about 13–16 brix, and Dutch round cantaloupe has a sweetness of over 14 brix).

Producing cantaloupes that meet export standards is such a feat, but the pre-processing, packaging, and post-harvest preservation are also paid special attention to by Unifarm. Currently, Unifarm products, after being harvested, are pre-processed, classified, packaged, and preserved in cold storage according to food hygiene and safety standards, meeting the quality requirements of domestic and foreign customers in each specific market.

Accordingly, after being harvested, cantaloupes are immediately brought to the packing house. Damaged fruits are removed, and the remainder is washed in a sink containing chlorine. Then, the fruit is dipped in a solution of natamycin (E235), a natural anti-fungal matter for food accepted worldwide. Next, the product is packaged and stored at 5–120°C, depending on the appropriate temperature for each melon variety.

Particularly, Unifarm is the only company in Vietnam that applies agricultural product preservation technology using modified atmosphere packaging (MAP) with good quality during storage and transportation. Thanks to the process of research and experimentation with MAP technology, the average preservation time of cantaloupes is extended to more than 15 days with the same quality as when just harvested, making it convenient for storage, long-distance transportation, or export while ensuring food safety and hygiene and preserving product nutrition compared to other preservation methods.

After being harvested, the cantaloupes are assigned a traceability code. Customers only need to use their smartphones to scan the QR code, and all information about the origin, process, and growing time is fully displayed. It is also the kindness and transparency of farmers who dare to think, dare to do, and dare to affirm to consumers about clean and quality products.

Thanks to its high and stable quality and preservation with advanced technology, Unifarm Cantaloupe was quickly present in most major retail systems in Vietnam, including Co.opmart, Aeon, Lotte, BigC, WinMart, MM Mega Market, etc.

Not only conquering the domestic market, Unifarm Cantaloupe has been exported to Singapore since 2018. Unifarm is the first Vietnamese agricultural company to export cantaloupe to this market.

Unifarm builds its brand based on the principle of protecting the rights and health of consumers. Accordingly, all Unifarm products must ensure food safety through standards such as VietGAP, Global GAP, etc.

In addition to cantaloupe, Unifarm bananas have also been exported abroad. Since 2014, Unifarm has exported its first containers of bananas to South Korea and China. In 2015, Unifarm exported its first container of bananas to Japan. Exporting bananas to Japan is the result of the company's tireless efforts in applying scientific and technical advances to growing and creating banana products that meet international standards and pass the strict requirements of the Japanese market.

In 2017, Unifarm signed an exclusive cooperation agreement with Dole Asia Holdings to use the Dole label on banana products in the Vietnamese market and deployed a banana growing area on a scale of 1,000 hectares to export to Asian markets.

From the initial one hectare, as of now, Unifarm has had over 20 hectares of high-tech cantaloupe production. Each hectare currently yields an average revenue of more than VND 2 billion/year.

According to Mr. Pham Quoc Liem, General Director of Unifarm, more than 10 years of diligently applying modern science, techniques, and technology to produce high-yield, good-quality cantaloupe products according to international standards are the basis for Unifarm to confidently participate in the One Commune One Product (OCOP) program. In 2021, Unifarm Cantaloupe was granted 4-star OCOP certification. Currently, Unifarm is completing procedures for the company's cantaloupe product to be certified with a 5-star OCOP.

“OCOP is an interesting program, originating from some countries such as Japan, South Korea, etc., and being implemented in Vietnam. In addition to bringing tangible values such as markets, improving product value, customers for agricultural workers, etc., OCOP products also represent the culture of each region. When Unifarm's cantaloupe product is certified with a 4-star OCOP, it means that this is considered a unique product of my hometown, Binh Duong, thereby stimulating customers to learn the story of creating the product. Therefore, making OCOP products is not only an economic story but also contains cultural resonance," Mr. Pham Quoc Liem shared.

Unifarm's goal when participating in the agriculture sector is to find models with high productivity, quality, and economic efficiency, then replicate them for people inside and outside the province. Unifarm never has the intention of competing with or replacing the role of farmers.

Achieving OCOP product certification is within reach for Unifarm. However, for many other subjects, obtaining OCOP certification for their products will be much more difficult because many factors must be met, including production techniques, standards, markets, etc.

Therefore, in recent times, Unifarm has invited many good domestic and foreign experts to experiment with many farming models. Thereby, effective production models have been found for products such as cantaloupe, bananas, etc.

With these models, Unifarm not only focuses on pure production but also must build a systematic supply chain for each product, including farming, post-harvest technology, logistics (transportation, warehouse logistics, and distribution system), and develop domestic and foreign markets. That is an important reason why Unifarm's cantaloupe product has been certified as OCOP.

Pursuing the goal of accompanying farmers to build and develop modern agriculture for the health of consumers and the future of Vietnamese farmers, Unifarm is actively supporting localities in developing agricultural product value chains.

Mr. Pham Quoc Liem shared that "Unifarm is helping many localities develop supply chains for products that are strengths of that locality, including products that Unifarm has not yet produced in the high-tech agriculture park in Binh Duong. With experience gained from practice, we will participate in accompanying and supporting local subjects if they wish to bring their products to participate in the OCOP program."

As for the cantaloupe product, Unifarm is now transferring techniques and signing contracts to consume products for many high-tech cantaloupe production farms in Binh Duong province and in provinces such as Lam Dong, Tay Ninh, Can Tho city, etc.

In addition to organizing production and transferring technical advances, Unifarm is also organizing "agricultural knowledge tourism" activities right at An Thai High-Tech Agriculture Park in An Thai commune, Phu Giao district, Binh Duong province.

Developing the "agricultural knowledge tourism" model is part of Unifarm's long-term strategic direction. The company's leaders hope that An Thai High-Tech Agriculture Park will be a source of inspiration to arouse the love of agriculture in Vietnamese people, especially the younger generation.

With "agricultural knowledge tourism," the company brings young people to the farm so that they can understand agriculture and form a love for agriculture, thereby creating a class of young intellectuals to participate in agriculture and helping Vietnam become a leading agricultural country in the world.