June 14, 2025 | 17:13 GMT +7

June 14, 2025 | 17:13 GMT +7

Hotline: 0913.378.918

June 14, 2025 | 17:13 GMT +7

Hotline: 0913.378.918

VRG will soon achieve the four goals of green growth and sustainable development for 2023-2030. Photo: Thanh Son.

The first goal is to focus on reducing greenhouse gas emissions. VRG has manufacturing fields such as rubber processing, technical product manufacturing, and wood factories. These production activities generate greenhouse gases. VRG aims to reduce greenhouse emissions by at least 15% by 2030 compared to 2023 and by 50% by 2050.

The second goal is to green the supply chain. VRG strives to ensure that by 2030, 60% of rubber forest areas will be certified with national or international forest certificates, such as VFCS, FSC, etc., and 100% will have credentials by 2050.

The third goal is to green the production process. To achieve this goal, VRG focuses on using renewable energy, reducing fossil energy, or converting to green, environmentally friendly production technologies to reduce dependence on fossil energy. By 2030, VRG will decrease by 15%, and by 2050 will decrease by 30% compared to 2023

The ultimate goal is to green the transition process based on the principles of inclusive equality and strengthening resilience. According to VRG, the ability to withstand environmental changes is crucial for businesses. Any company must ensure responsibility towards the environment and society during the development process.

Nowadays, businesses must improve social responsibility instead of only caring about economic benefits. With the goal of green growth and sustainable development, VRG ensures its survival and development in the future.

Mr. Huynh Tan Sieu, Head of the Industry Department, VRG, stated three main solutions groups based on the above four goals. First, improve performance and energy efficiency. VRG is researching and issuing a comprehensive strategy to change machinery equipment and technological processes.

Second, review and adjust the planning of production technologies, focusing on new technologies that bring high productivity, are environmentally friendly, and get more economic benefits than conventional equipment currently.

Third, handle environmental issues well. For example, you properly take waste from production and business processes, classify waste from sources, and reuse trash from production processes.

"If the above three solutions are well implemented, VRG will soon achieve the four goals of green growth and sustainable development for 2023-2030," Mr. Sieu said.

In addition to the rubber sector, VRG also participates in many production activities in other industries, such as rubber conveyor belts, tires, foam mattresses, and gloves. Some members of VRG have also joined the wood production industrial park business. However, Mr. Sieu affirmed that VRG members always prioritize green and sustainable construction and development resources.

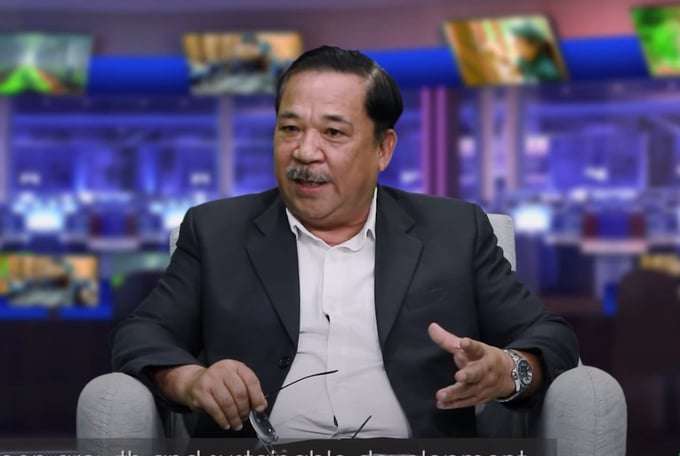

Huynh Tan Sieu, Head of the Industry Department, VRG.

Currently, with the world's requirements for green growth and sustainable development, if VRG wants to participate in the global supply chain, it must build the Group's image associated with the above goals.

"We are researching, reviewing, and balancing financial resources to enhance the promotion of the results we have achieved," Mr. Sieu emphasized.

In the long term, VRG wants to become a corporation with high economic efficiency, environmental responsibility, and primarily social responsibility. Mr. Sieu believes these factors will help VRG integrate more deeply into the world economy while effectively taking advantage of incentives from FTAs, especially new-generation FTAs.

Recently, the EU issued EUDR regulations on anti-deforestation. This regulation directly affects the rubber industry. On that basis, VRG believes there must be early and appropriate responses to participate promptly in the supply chain.

Currently, VRG has 41 wastewater treatment systems reaching column A standards. Many VRG member companies are promoting the reuse of this wastewater source in production activities at factories. At Binh Long Rubber Company Limited (Binh Phuoc), almost all treated wastewater has been reused to wash latex pus. At Dau Tieng Rubber Company Limited (Binh Duong), in 2022, over 30% of sewage was reused after treatment to meet column A standards.

In addition to reusing wastewater in factories, the treatment and reuse of wastewater at rubber latex delivery stations is also being implemented by many companies. Accordingly, the entire amount of water used to rinse tools and latex-receiving floors is collected in the pus decanting pit. After removing all remaining latex, the water will be preliminarily treated to irrigate the rubber garden.

VRG builds a "clean industrialization" strategy by reviewing and adjusting the leading business sector and business plans, using resources economically and effectively. At the same time, it promotes the development of green agriculture and green industry with a structure of human resources, technology, and equipment that ensures environmentally friendly principles.

Translated by Tuan Huy

/2025/06/12/3721-2-202745_83.jpg)

(VAN) TH made an impression at Seoul Food 2025 with its line of natural beverages, paving the way for Vietnamese food products to enter the South Korean market.

(VAN) Soc Trang's success in rice exports stems from a strategy of developing fragrant and specialty rice cultivation areas and standardizing production toward low-emission practices.

/2025/06/11/1311-5-120811_839.jpg)

(VAN) The pig farming industry is facing the challenge of comprehensive restructuring to meet requirements for quality, safety, traceability, and market expansion both domestically and for export.

(VAN) Vietnam considers participating in ALGROALBA in order to expand agricultural production, coordinate the assessment and effective exploitation potential land.

/2025/06/05/5314-1-184727_407.jpg)

(VAN) From seemingly worthless fish scales and skin, enzymes and lactic ferments can transform by-products into peptides, opening a sustainable, effective business direction and elevating Vietnamese seafood.

(VAN) TTC AgriS and IFC signed a strategic partnership to develop a sustainable agricultural value chain, aiming to achieve the Net Zero target by 2035.

(VAN) Seafood by-products are opening a new path, combining green growth and technological innovation to enhance the industry's value.