May 14, 2025 | 10:06 GMT +7

May 14, 2025 | 10:06 GMT +7

Hotline: 0913.378.918

May 14, 2025 | 10:06 GMT +7

Hotline: 0913.378.918

The demand for imported pellets will rise significantly because the South Korean government's 10th power plan dictates that wood pellets will make up 57.64% of all bioenergy between 2022 and 2036.

Director of Poseung Biomass Cogeneration Plant giving an introduction to the operation of the plant. Photo: Chu Khoi.

Within the framework of the Korean program to study and share international experiences on bioenergy development under BEM's project for "Climate protection through sustainable bioenergy market development in Vietnam", we visited Poseung Biomass Cogeneration Plant in Asan National Industrial Complex, Poseung, Gyeonggi Province, Korea.

This is a 100% bio-solid fuel (Bio-SRF) power plant, designed to produce up to 174.3 tons of steam and 43.2 MW of electricity per hour using wood biomass as a fuel source. The plant, which was designed for a 30-year operation cycle, started construction in March 2016 and went into commercial operation in March 2018.

A corner of Poseung Biomass Cogeneration Plant. Photo: Chu Khoi.

The director of Poseung Biomass Cogeneration Plant reported that the total construction cost for the plant was USD 22 million, including USD 6 million of equity and USD 16 million of loans from the project capital. Accordingly, 63% of the plant's investment capital is owned by LX International; the remaining 37% is foreign capital.

USD 19 million of the total investment capital went towards equipment and construction, and the remaining USD 3 million went towards operation and licensing costs. The plant's main equipment installed includes turbines manufactured by GM India, generators imported from India and boilers manufactured by domestic firms. The plant has to pay a land rental cost of approximately USD 100,000 per year.

According to the technical staff, the plant's operating process begins with burning biomass fuel; the product of which will provide heat to the water boiler. The water in the boiler is then heated to steam at a temperature of 500 degrees Celsius. Subsequently, part of the steam enters the turbine to energize the generator, which will produce electricity with a capacity of 30 MWh. The remaining steam will be separated to supply other factories in the industrial zone.

The plant sells electricity to the Korea Electric Power Corporation and sells steam to companies operating in the Asan National Industrial Complex in Poseung.

Hot steam will travel through ten pipes to ten different companies to support the operation of steam-powered machinery and equipment. Steam is produced at 500 degrees Celsius at the power plant, but it is delivered to companies at 200 degrees Celsius. In the final stages, condensed steam is collected and delivered back to the power plant.

Korea will gradually switch to using power from pellets. Photo: Chu Khoi.

According to the technical staff, the exhaust gas generated after the biomass burning process will be reduced to chlorine, sulfur HCI, and carbonate components. Before being released into the environment, the exhaust gas goes through a machine that uses activated carbon to filter harmful compounds such as furans, dioxins, and dust.

The Director estimates that the power plant needs roughly 35 tons of fuel per hour on average. “Due to Korea's Netzero commitment and the Russia - Ukraine conflict, the price of wood pellets has skyrocketed. As a result, only 10% of the fuel is wood pellets; the remaining 90% is wood chips from construction waste, household waste and forest by-products such as dry branches or trees damaged by forest fires”.

The plant needs 1.5 tons of biomass to produce 1 MW of electricity. The company uses around 260 thousand tons of biomass every year. The Director of Poseung Biomass Cogeneration Plant commented on the profit efficiency: The plant runs constantly for 310 days each year, or 7,400 hours. The company sells roughly 300,000 MWh of electricity each year. The company's Internal rate of return (excluding interest and equipment depreciation) falls between 10 and 12% a year and the actual IRR falls between 6 and 7% a year.

According to Dr. Lee Soo Min, Senior Researcher in the Department of Forest Industrial Materials under the National Institute of Forest Science, Korea is converting its energy source in order to fulfill its commitment to reduce carbon dioxide emissions.

Korea is currently the main import market for Vietnamese wood pellets. Photo: TL.

Biomass energy currently accounts for less than 1.5% of Korea's total electricity production. The main form of biomass electricity in Korea is thermoelectricity; namely, burning wood pellets to generate heat and electricity. Although this form of energy only accounts for a small proportion, the capacity of power generation using pellets in Korea has increased rapidly in recent years.

Korea currently has a total of 4.5 million tons of wood pellets, including import and domestic production. However, domestic production only meets 15.8% of the demand for pellets by power plants.

There are currently 20 wood pellet production facilities in Korea, with 3 large-scale facilities producing 1 million tons annually, and 17 small-scale facilities producing less than 10,000 tons annually.

“In 2022, Korea imported roughly 3.78 million tons of wood pellets, which is an increase of 600,000 tons compared to 2021. 95% of Korea's wood pellet import originates from Indonesia, Vietnam and Malaysia. More specifically, Korea imported approximately 2.2 million tons of wood pellets from Vietnam in 2022, accounting for 80% of the total import volume," Dr. Lee Soo Min said.

Korea's rising energy consumption offers Vietnam a significant export opportunity. Photo: TL.

Regarding Korea's reliance on imported Vietnamese wood pellets, Dr. Lee Soo Min offered an explanation: "Korea's has a total land area of 10 million hectares, including 6.3 million hectares of forests. The country produces 4.3 million tons of raw wood annually. Korea's current annual wood production is only one tenth of that of Vietnam. On the other hand, Vietnam has 33.8 million hectares of natural land area, including 14.8 million hectares of forests. Vietnam's annual raw wood yield ranges from 30 to 57.3 million cubic meters.

According to Korean experts, the Korean renewable energy market, including wood pellets, is driven by government policies. Namely, the Korean government's 10th power plan dictates that wood pellets will make up 57.64% of all bioenergy between 2022 and 2036.

Korea's demand for wood pellets is projected to reach 5 million tons in 2023, with 743 thousand tons from domestic production, and 4.17 million tons from imports.

Vietnam has an abundant source of wood materials, which can facilitate pellet production for export to Korea. Photo: TL.

"The number of power plants using wood pellets in Korea is steadily rising. As a result, demand for wood pellets in Korea is expected to increase rapidly in the following years, reaching 6 million tons by 2025", said Dr. Lee Soo Min.

According to Dr. Lee Soo Min, coal-fired power plants in Korea are producing nearly 40% of the total national electricity output, and using 100 million tons of coal per year. The Korean government plans to end coal-fired power entirely by 2030.

Consequently, force coal-fired power plants must replace their technology and equipment to adopt wood pellets as a fuel source. If all coal-fired power plants in Korea are converted into pellet thermal power, the demand for wood pellets will be substantial, reaching several hundred million tons every year.

“However, I do not believe it is possible to replace all coal-fired thermal power with pellet thermal power. At best, only 10% of them would be converted. But even with only a 10% conversion rate, the demand for wood pellets will be significant in the immediate future," said Dr. Lee Soo Min.

Korean people are concerned about the unsustainable production of wood pellets in Vietnam, due to its dependence on solid wood instead of by-products from the wood processing industry. Photo: TL

Korea will increase its import of wood pellets from Vietnam. However, many Korean people have expressed concern over the unsustainable production of wood pellets in Vietnam as well as other Southeast Asian countries. Accordingly, these countries rely extensively on solid wood instead of by-products from the wood processing industry, leading to competition for raw materials with the wood product industry.

In response to concerns regarding the lack of sustainability in power from wood pellet, Dr. Lee Soo Min suggested Vietnam and Korea to cooperate in several solutions including: Linking forest biomass policy with the promotion of sustainable forest resources; establishing a governance system that includes carbon neutrality, ESG and market transparency; strengthening the legal timber trade promotion system and so on.

Translated by Nguyen Hai Long

(VAN) Use of high-quality broodstock and biotechnology is regarded as the most effective approach to ensuring sustainable and economically viable shrimp aquaculture ahead of climate change and the emergence of increasingly intricate disease patterns.

(VAN) Carbon farming is a form of agricultural practices that helps absorb more greenhouse gases than it emits, through smart management of soil, crops, and livestock.

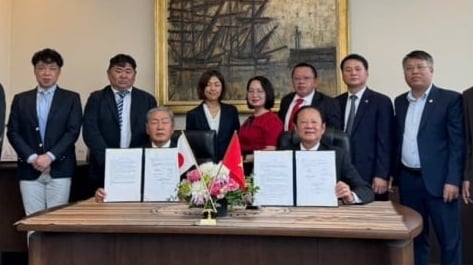

(VAN) This is a key content of the Memorandum of Understanding recently signed between the Vietnam Fisheries Society and Kunihiro Inc of Japan.

(VAN) To achieve the goal, local authorities and businesses in Kon Tum province have fully prepared the necessary conditions for the new Ngoc Linh ginseng planting season.

(VAN) Jiangsu province is gearing up to host training programs in Phnom Penh, the capital of Cambodia, this year to establish the Fish and Rice Corridor.

(VAN) Le Hoang Minh, representing Vinamilk, shared the company's experience in energy saving and green energy transition for production at a workshop held during the P4G Summit.

(VAN) Businesses emphasize fairness and equality when integrating social factors into their sustainable development strategies.