June 21, 2025 | 03:02 GMT +7

June 21, 2025 | 03:02 GMT +7

Hotline: 0913.378.918

June 21, 2025 | 03:02 GMT +7

Hotline: 0913.378.918

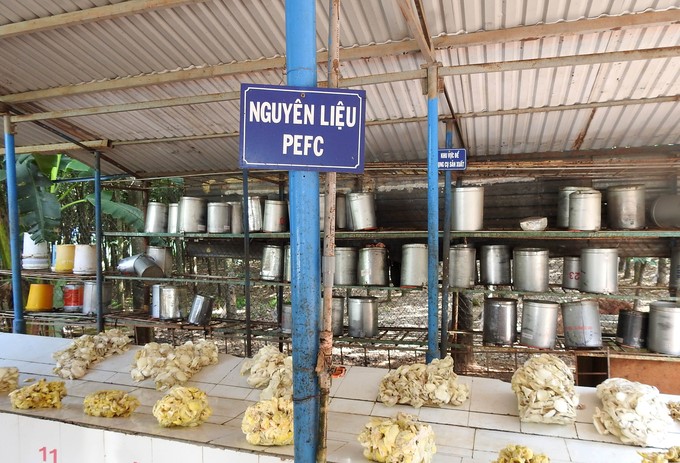

Workers at Quan Loi Farm wash tools after importing rubber latex. Photo: Thanh Son.

On the journey to Binh Phuoc to learn about the process of implementing sustainable forest management and other sustainable development programs in some subsidiary companies of the Vietnam Rubber Group (VRG), Quan Loi Farm of Binh Long Rubber Co., Ltd. impressed us with its cleanliness, no scattered rubber latex, and no characteristic odor commonly found in private rubber purchasing points.

That station achieved that cleanliness thanks to a wastewater treatment system aimed at meeting the requirements of the sustainable rubber forest management program. After delivering latex, the production tools and latex receiving floors are washed by workers right at the station. The entire amount of this wastewater is collected in the latex manhole to collect the remaining latex and preliminarily treat the wastewater before being used to irrigate the rubber garden.

Mr. Pham Anh, Deputy General Director of Binh Long Rubber Co., Ltd., shared that thanks to the wastewater treatment system, the remaining latex in the wastewater has been recovered. As a result, wastewater used to irrigate rubber gardens no longer pollutes the environment. Economic efficiency is also increased by taking advantage of rubber latex in the manholes, thereby increasing the income of workers.

A tidy and clean latex import station at Phu Rieng Do farm. Photo: Thanh Son.

According to Mr. Truong Van Hoi, Deputy General Director of Phu Rieng Rubber Co., Ltd., thanks to the development of a sustainable forest management program, latex import stations, the sloppiest places in rubber companies, have become clean without environmental pollution and rubber smell.

Binh Long Rubber Co., Ltd., is one of the first three companies selected by VRG to implement the sustainable rubber forest management program in 2019. After being assigned the task, the company coordinated with the Silviculture Research Institute (SRI) to carry out the experiments at two farms, namely Loi Hung farm and Quan Loi farm, with a total area of 3,940 ha.

Deputy General Director Pham Anh said that in the first period of program implementation, the company faced many difficulties and obstacles. Specifically, the standards of the PEFC forest management certificate have not been specified according to the characteristics of Vietnam. Therefore, the entire system of documents and regulations must follow the template of the international PEFC system, so it is not easy to implement.

However the largest difficulty is with people, because sustainable development is a new concept for most of the company's staff. Staff and leaders at the grassroots level have to perform more jobs that were not available before.

With the attention and drastic direction of VRG's leadership, the dedicated guidance of SRI, and the determination of the leadership of Binh Long Rubber Company, by 2021, the company’s entire rubber area of nearly 15,000 ha had been issued the VFCS/PEFC-FM sustainable forest management certificate. Also assigned by VRG to implement a sustainable rubber forest management program from 2019 to now, Phu Rieng Rubber Company is maintaining and effectively applying the VFCS/PEFC-FM forest management certificate for 10 farms with a total area of over 17 thousand ha.

In addition to implementing sustainable rubber forest management, over the years, both Binh Long Rubber Company and Phu Rieng Rubber Company have implemented and been granted the PEFC-CoC Chain of Custody Certificate for factories.

Up to now, VRG has had nearly 110 thousand ha of rubber granted the VFCS/PEFC-FM Sustainable Forest Management Certificate. Photo: Thanh Son.

By the end of 2022, VRG will have 17 subsidiary units with nearly 110 thousand ha of rubber that have been granted the Sustainable Forest Management Certificate according to national standard VFCS/PEFC-FM and 30 processing factories that have been granted the Chain of Custody Certificate according to international standard PEFC-CoC.

The selling price of VGR’s rubber latex with a sustainable development certificate compared to normal latex is not much different, and the economic efficiency is still quite modest, except for Binh Long Rubber Company. However, VGR's subsidiary companies implementing sustainable rubber forest management and chain of custody all believe that this is a good preparation for the future.

According to Mr. Truong Van Hoi, currently, many markets require imported rubber or wood products to have sustainable certifications for rubber and wood materials. This is a mandatory trend in the near future; unidentified products will not be sold. Therefore, applying for sustainable forest management certificates is preparation for market requirements for certified products.

Mr. Pham Anh said that Binh Long Rubber Company's leadership has determined that building a VRG rubber brand with the sustainable development certificate is a necessary and strategic task for the group's prosperous development in general and the company in particular. This will thus ensure the survival of the company's production and business in the future.

Translated by Huyen Vu Thu

![Turning wind and rain into action: [9] Digitizing hydrometeorological data in response to climate change](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/06/17/z6704423696987_15fd32ffc26d590d204d520c9dac6786-nongnghiep-165943.jpg)

(VAN) Farmers have begun accessing hydrometeorological applications to adjust their cropping schedules, aiming to ensure productivity and adapt to climate change.

![Turning wind and rain into action: [8] Real-time salinity detection and early warning technology](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/06/17/z6704423696987_15fd32ffc26d590d204d520c9dac6786-nongnghiep-151127.jpg)

(VAN) Thanks to the integration of modern hydrological-hydraulic models, remote sensing technologies, and artificial intelligence, the accuracy of hydrological forecasting has significantly improved.

![Turning wind and rain into action: [7] Early disaster warnings help marine farmers minimize losses](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/06/17/z6704423696987_15fd32ffc26d590d204d520c9dac6786-nongnghiep-142942.jpg)

(VAN) In recent years, thanks to early disaster warnings and forecasting, marine farmers in Khanh Hoa province have been able to reduce risks and losses, thereby improving production efficiency.

![Turning wind and rain into action: [6] ‘Four on-the-spot’ disaster management software](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/06/17/e5a48259d6a262fc3bb3-nongnghiep-183800.jpg)

(VAN) By simply activating the scenario on the disaster management software, the relevant authorities immediately know how many households need to be evacuated, where to evacuate them to, and by what means of transportation…

![Turning wind and rain into action: [5] Hue applies modern technology in disaster forecasting](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/06/17/z6704423696987_15fd32ffc26d590d204d520c9dac6786-nongnghiep-093938.jpg)

(VAN) In Hue city, modern technology has recently been applied in meteorological and hydrological forecasting and warning, helping to reduce the damage caused by natural disasters.

(VAN) A cutting-edge farming technique being implemented on an experimental ranch in Arizona's Sonoran Desert has already saved a billion gallons of water over five years, according to Civil Eats.

(VAN) Poultry and pig production and the environment can be boosted through enhanced water technology, according to new research.