May 20, 2025 | 23:53 GMT +7

May 20, 2025 | 23:53 GMT +7

Hotline: 0913.378.918

May 20, 2025 | 23:53 GMT +7

Hotline: 0913.378.918

Machine-transplanted rice fields help farmers save 15-20% of costs, thanks to the reduction of seeds, fertilizers, and pesticides while sustaining the desired productivity and profits. Photo: Trung Chanh.

Having experienced dozens of rice crops in a row, farmers in Binh Hieu only choose the method of sparse transplanting by machine instead of sparse sowing or line sowing.

Mr. Nguyen Van Hien, Director of Binh Hieu Agricultural Cooperative deemed this the most advanced rice production solution. While sparse sowing requires 100 - 120 kg of rice seed/ha, line sowing also takes 80 - 90 kg/ha. And also in comparison to the previous practice of densely sowing 180 - 200kg of seed rice/ha, these methods have reduced a large amount of seed costs, but machine transplanting is still the most effective method as it only requires 50 kg of seed/ha to make seedlings.

Machine transplanting creates a reasonable density for the rice plants, helping them grow well and attain great quality. Farmers profit up to VND 35 million VND/ha in the 2021 - 2022 spring crop. Photo: Trung Chanh.

“Costs are skyrocketed in this crop. If you add up all the costs from seed varieties, materials, care to harvest, each 360 m2 of rice costs approximately VND 2.5 million. The yield is 1.1 tons/360 m2, and the selling price is VND 6,800/kg (thanks to seed production, businesses offer to pay VND 1,000 higher than the market price for every 1 kg produced). The total revenue is approximately VND 7.5 million, equivalent to a profit of VND 5 million/360 m2 This means that farmers can pocket VND 35 million/ha.

“It’s thanks to machine transplanting that the rice plants are evenly sparse, and farmers can reduce costs in investment and production. New rice varieties also contribute to the increase in profit. If sowing is as thick as before, farmers will only profit VND 1 - 2 million at best,” said Mr. Ho Van Hong, a member of Binh Hieu Agricultural Cooperative.

Mr. Ho Van Hong buys coco dust himself to make seedlings for his fields and only hires a machine transplant service to reduce costs. Photo: Trung Chanh.

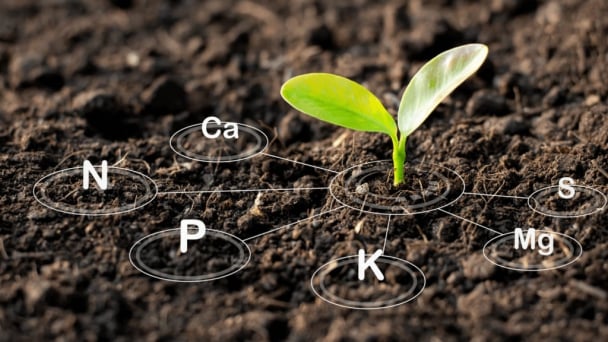

In the context that fertilizer prices have skyrocketed up to VND 1.2 - 1.3 million per bag at present, sparse transplanting is the most effective solution to reduce the amount of fertilizer. The rice yield is still high upon harvest while the investment costs are reduced, so input costs are lowered as followed, ensuring farmers’ expected profit.

The application of tray plating and machine sparse transplanting in rice production is becoming more and more popular in Hau Giang and neighboring provinces.

Mr. Tran Hoang Phuc, Head of Agricultural Extension and Agricultural Services Station in Long My Town (Hau Giang), said that many farmers here are now familiar with the machine transplanting service and clearly see its benefits.

“Application of tray plating and machine transplanting in rice production will help farmers save investment costs by 15-20% by reducing rice seed, fertilizer, and pesticide. Rice fields are sparsely planted, the stem is strong and well-developed, pests and diseases are greatly reduced, the plants rarely wither or fall. The yield is 50-100 kg/ha higher than other forms of sowing. The grain is firm and bright, and thus the selling price is higher."

Mr. Vo Xuan Tan, Director of Hau Giang Agricultural Extension and Service Center, said that synchronous mechanization models in rice production, including planting, tending and harvesting, have helped reduce rice production cost effectively.

Mr. Truong Tan Tri (right), a member of the machine transplanting service team of Binh Hieu Agricultural Cooperative and Mr. Tran Hoang Phuc, Head of the Agricultural Extension Station of Long My town, checking the seedlings to prepare for the 2022 summer-autumn rice crop. Photo: Trung Chanh.

The rice transplanter model in Vinh Tuong ward (Long My town) is a mentionable prime example. The initial cost is approximately VND 2.5 - 3 million/ha higher compared to regular sowing. But in return, it reduces the amount of rice seeds, fertilizers, and pesticides. The yield is much higher than that of the normal sowing field (1.5 tons/ha, 2021 summer-autumn crop). The selling price is also increased, resulting in this model helping farmers earn a profit of VND 8 million/ha.

Moreover, the use of drones in the pesticide spraying stage serves as a foundation for farmers to gradually apply high technology and awaken a sense of applying mechanization in agroproduction. It helps to limit the risk of pesticide overdose and can reduce the amount used by 10-15% per unit area.

Translated by Samuel Pham

(VAN) Japan's grant aid project contributes to capacity building, promoting organic agricultural production, and fostering sustainable community development in Dong Thap province.

(VAN) For years, the CRISPR-Cas9 genome technology has been reshaping genetic engineering, a precision tool to transform everything from agriculture to medicine.

(VAN) Vietnam aims to become a 'leader' in the region in the capacity and managing effectively soil health and crop nutrition.

![Reducing emissions from rice fields: [Part 1] Farming clean rice together](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/05/05/z6509661417740_a647202949c539012a959e841c03e1d3-nongnghiep-143611.jpg)

(VAN) Growing clean rice helps reduce environmental pollution while increasing income, allowing farmers to feel secure in production and remain committed to their fields for the long term.

/2025/05/19/5136-1-144800_230.jpg)

(VAN) The Nghe An Provincial People's Committee has just approved the list of beneficiaries eligible for revenue from the Emission Reductions Payment Agreement (ERPA) in the North Central region for the year 2025.

(VAN) 14 out of 35 domesticated elephants in Dak Lak province have had their living conditions improved, with 11 of them currently participating in the non-riding elephant tourism model.

(VAN) Muong Nhe Nature Reserve hopes that being upgraded to a national park will lay the foundation for forest protection efforts to be carried out in a systematic, modern, and sustainable manner.