May 21, 2025 | 07:42 GMT +7

May 21, 2025 | 07:42 GMT +7

Hotline: 0913.378.918

May 21, 2025 | 07:42 GMT +7

Hotline: 0913.378.918

Technical training on producing organic fertilizer from straw was organized by Hue University of Agriculture and Forestry in collaboration with the International Rice Research Institute. Photo: Cong Dien.

Hue University of Agriculture and Forestry coordinated with the International Rice Research Institute (IRRI) to organize training and demonstration of technology and equipment for producing organic fertilizer from straw for farmers. The program was held at An Lo Agricultural Cooperative, Phong Hien commune, Phong Dien district, Thua Thien Hue province.

IRRI experts guided farmers on composting organic fertilizer from straw using a mechanized method and using finished organic fertilizer products in production. This method helps promote the process of processing and using straw towards circular agriculture and low carbon emissions in Thua Thien Hue province.

The composting process includes the following steps: Prepare straw and cow manure; Then mix and spray probiotics and cover with canvas.

Farmers then test the straw bed's temperature, humidity, and pH. Depending on temperature and humidity, stir a second time after 10-15 days. Cover with a tarp and keep warm.

After cooling, about 45 days from the first mixing, farmers can use this organic fertilizer in the field.

In Thua Thien Hue province, straw has yet to be used optimally. A small portion of straw is used as mushrooms, animal feed, biological bedding, mulching the field to retain moisture, etc. Much of the straw is burned in the area after harvest, causing waste and possibly affecting the environment.

The Department of Agriculture and Rural Development of Thua Thien Hue estimates that the province has more than 620,000 tons of straw annually. This is a considerable source of agricultural by-products that can be reused for many purposes.

Mr. Nguyen Ba, Director of An Lo Agricultural Cooperative, one of the students attending the training program, admitted that changing the traditional habit of handling straw is extremely necessary, especially in the agricultural sector. The industry is promoting green production, moving towards circular agriculture models.

"Very excited to be guided by foreign experts on simple, cheap, and practical measures. Hopefully, we can soon implement and replicate this approach," he said.

Mr. Ba estimates that the method guided by IRRI shortens the composting time to half compared to the traditional manual composting process.

Demonstration of technology and equipment for producing organic fertilizer from straw at the training program. Photo: Cong Dien.

Thua Thien Hue province recently issued programs to limit straw burning after the rice harvest. The area aims to attract 50 communes and wards to participate in processing waste into fertilizer at home by 2024.

In addition, Thua Thien Hue's agricultural sector aims to develop a project to make the most of straw resources and have policies to support farmers using probiotics in straw treatment, reducing landfilling and Cost savings.

Statistics from IRRI show that out of 47 million tonnes of straw per year, only 20 percent is used as straw mushroom beds, cattle feed, and cushions for fruit transportation. The rest is either burnt or buried in rice fields.

In Vietnam, among the rice straw management technologies, the straw compost turner developed in collaboration with IRRI converts rice straw into compost. This technology was developed under IRRI's Scalable straw management options for improved livelihoods, sustainability, and low environmental footprint in rice‐based production systems projects.

The Ministry of Agriculture and Rural Development (MARD) and IRRI also recently successfully developed a technical guideline titled 'Handbook on Rice Straw Management towards Circular and Low Emission Agriculture in Mekong River Delta.' Covering rice straw management protocols for implementation in the whole Mekong River Delta region, this effort is intended to contribute to the Vietnam government's proposal for the "Sustainable Development of One Million Hectares of Specialized High Quality and Low Carbon Rice Production Areas under the Green Growth Agenda in the Mekong Delta Region up to 2030".

Straw treatment is one of the issues that Minister Le Minh Hoan pays special attention to when building a sustainable rice industry. He says that Vietnam's rice industry aims for quality, circularity, and low emissions. These concepts are not new, but they sketch an entire journey to approach the trend of the times towards creating a rice brand in the international market.

From when the grain of rice is in the field to when it reaches the consumer, it is a close structure in the commodity chain. Whether that structure is sustainable depends on the industry ecosystem. In that ecosystem, people are the decision-makers.

In addition to reorganizing production, Minister Le Minh Hoan called for the entire supply chain needs associated with the collective economy and land concentration.

"Circular agriculture means having no such thing as waste. Straw can become substrate, create electricity, or become construction materials. The development of the rural economy creates more livelihoods for rice growers, bringing benefits to people not only from the grains but also from other parts of the rice plant", Mr. Hoan said.

Translated by Tu Quyen

(VAN) Japan's grant aid project contributes to capacity building, promoting organic agricultural production, and fostering sustainable community development in Dong Thap province.

(VAN) For years, the CRISPR-Cas9 genome technology has been reshaping genetic engineering, a precision tool to transform everything from agriculture to medicine.

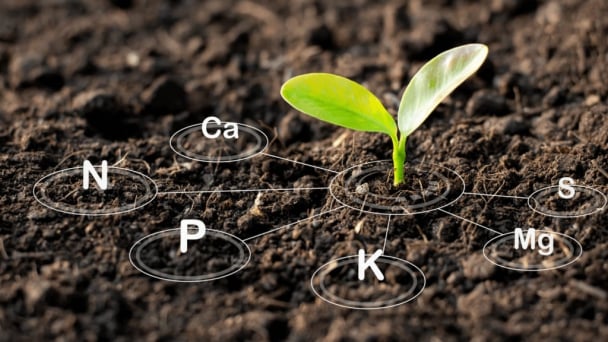

(VAN) Vietnam aims to become a 'leader' in the region in the capacity and managing effectively soil health and crop nutrition.

![Reducing emissions from rice fields: [Part 1] Farming clean rice together](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/05/05/z6509661417740_a647202949c539012a959e841c03e1d3-nongnghiep-143611.jpg)

(VAN) Growing clean rice helps reduce environmental pollution while increasing income, allowing farmers to feel secure in production and remain committed to their fields for the long term.

/2025/05/19/5136-1-144800_230.jpg)

(VAN) The Nghe An Provincial People's Committee has just approved the list of beneficiaries eligible for revenue from the Emission Reductions Payment Agreement (ERPA) in the North Central region for the year 2025.

(VAN) 14 out of 35 domesticated elephants in Dak Lak province have had their living conditions improved, with 11 of them currently participating in the non-riding elephant tourism model.

(VAN) Muong Nhe Nature Reserve hopes that being upgraded to a national park will lay the foundation for forest protection efforts to be carried out in a systematic, modern, and sustainable manner.