May 29, 2025 | 16:04 GMT +7

May 29, 2025 | 16:04 GMT +7

Hotline: 0913.378.918

May 29, 2025 | 16:04 GMT +7

Hotline: 0913.378.918

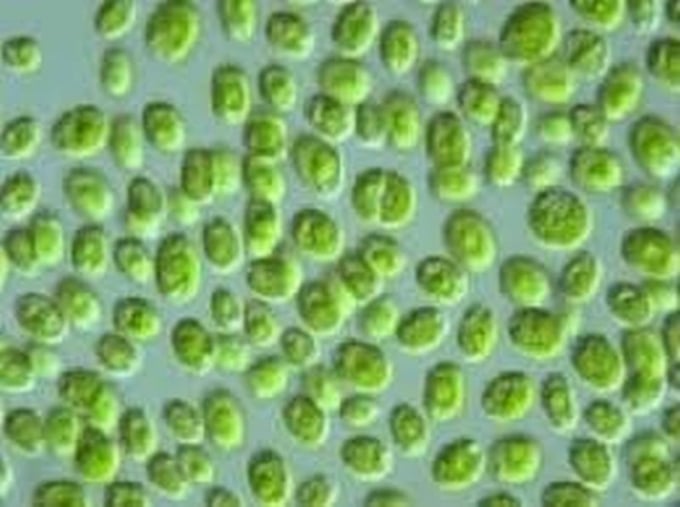

Microalgae are a rich source of nutrients for many aquaculture and seafood species and a potential raw material for the exploitation of highly bioactive substances for humans. Nannochloropsis is a genus of algae in the family Chlorellaceae, order Chlorellales, class Trebouxiophyceae, phylum Chlorophyta.

This genus has a very similar cell morphology to species of the genus Chlorella. Their cells are unicellular, spherical, and they reproduce asexually by dividing into two daughter cells about 2-4 µm in size.

This algae has a high content of eicosapentaenoic acid (EPA) (3.2% dry weight), ascorbic acid ( 0.8% dry weight) and vitamin B12 content that can meet the developmental needs of aquatic animals at an early stage of development.

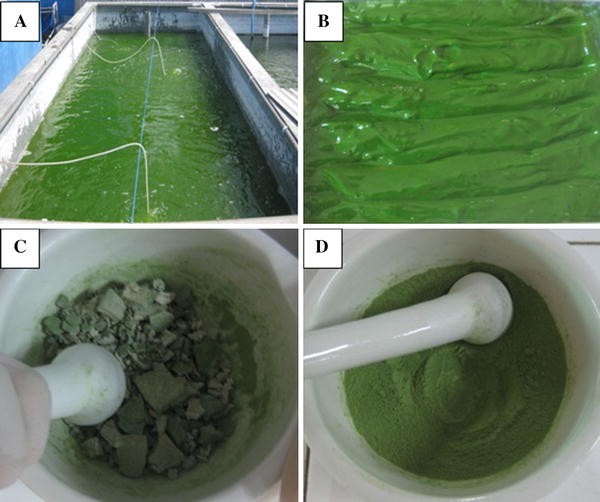

Algae biomass production technology is studied in a laboratory at the Research Institute for Marine Fisheries. Photo: BT.

Nannochloropsis oculata is considered an important food source for rotifers, some fish larvae and other crustaceans. Cultivation of this algae has been carried out in many parts of the world with many different methods. Current methods require high technology, modern and demand that farmers invest in machinery and high means. Moreover, farming productivity is volatile and unpredictable.

It is necessary to choose an easy-to-implement, high-yield farming method suitable for Vietnam's conditions. Besides, algal biomass yield as well as biochemical composition and content of their valuable biologically active compounds are all changed under different culture conditions such as nutrient environment, temperature, light, among others..., as well as growth phase and characteristics of cultured algae strains.

According to the research team of Dr. Nguyen Van Nguyen of the Research Institute for Marine Fisheries, the level of algae farming technology in Vietnam is pretty low while there is no centralized production facility and lack of equipment and techniques. Therefore, it is impossible to produce in large quantities or high density. The current farming method is mainly conducted within cement tanks, composite tanks with low efficiency.

Some localities adopt the model of rearing in nylon bags with improved but quite modest density, below 20 million tb/ml, which yields unstable profit due to modest production scale.

Microalgae samples are seen through a microscope. Photo: TL.

To handle such issues, the research team has tested and studied the two most promising technologies - intensive farming of algae with closed PBR photobioreactors; using artificial light and carefully controlling the environmental parameters. The outdoor farming model is simple, using natural light in the direction of optimizing light by using transparent materials with small diameter as containers such as nylon bags, cylindrical iron cage models combined with bags nylon.

In addition, the staff of the Research Institute for Marine Fisheries have also improved the algae biomass culture system in two directions. One is to grow algae in photogenic flasks designed from plastic and glass tubes of light bulbs, circulating the culture fluid in the pump system at a speed of 0.4 - 0.5m/s, with a capacity of each system reaching 250 - 500 liters.

The second is a nylon bag culture system with a diameter of 25 - 30cm, intending to optimize the energy use of algae for high-density growth. Both research directions are operated simply and conveniently in algal biomass production.

The research team developed a 7-step process to produce algae biomass before putting it into storage. Specifically:

Step 1, prepare the water. Seawater is adjusted to the salinity of 2.5 - 2.8%, then treated with chlorine 20 - 30ppm, continuously aerated for 24 - 48 hours to settle, check chlorine residue with Octolidin reagent and neutralize with Na2S2O3, filter by an activated carbon filter column system to create clean sea water. The treated water is used for 48 hours.

Step 2, prepare the environment. The f/2 medium is prepared according to Guillard's formula. The medium after reconstitution is autoclaved before use, except for the vitamin component. Supply nutrient medium at the rate of 1ml/l of culture water.

Cultivation of Nannochloropsis oculata algae under experimental conditions. Photo: TL.

Step 3, prepare the algae. After activation, the algae will be transferred to a triangular flask with a volume of 250 - 500ml and initial seed density of 1.25 - 1.5 million. The algae is grown in artificial light conditions, with light intensity of 1,500 - 2,000 Lux and is shaken twice a day.

After 6-7 days, proceed to increase the culture volume. Algae cultured at a volume of 250 - 500 ml will be transplanted into plastic bottles at a volume of 750 - 1,000 ml. Initial seed density is 1.75 - 2 million. Breeds are raised in artificial light conditions with light intensity of 2,000 - 2,500 Lux and aerated at a light speed.

After 7 days of culture, conduct intermediate propagation. Algae cultured at a volume of 750 - 1,000 ml will be transplanted into plastic bottles with a capacity of 5 - 6 liters. Aeration is conducted at a moderate speed all day. Initial seed density is 3 - 5 million. Breeds are raised in artificial light conditions with light intensity of 2,500 - 3,500 Lux. After 5-7 days, the seeds are transferred to biomass culture in large-scale tubular or plastic photo biosystems.

Step 4, prepare the system.

Hanging nylon bag system includes bag units with a suitable light path or bag radius of D=20cm, height h=120cm and volume of each unit V=37l. The bag system is designed with a steel hanger of 150cm high. The air ducts are connected to the air compressor and CO2 supply tank, and arranged along the upper bar of the mount, ensuring the air supply for the system operation.

The tubular Photobiol system consists of 2 rows of transparent glass tubes with a length of 2.6m installed parallel to each other. The glass tube after being connected is fixed on a wooden stand. Two rows of pipes are separated by 30cm, each row consists of 11 glass pipes connected by 24mm diameter PVC segments.

Currently, microalgae farming technology for aquaculture has been efficiently applied by many localities. Photo: ST.

The two rows of pipes are connected by U-shaped PVC segments. The lowest position is connected to the thick end of the pump and the highest position is connected to the PVC pipe transferred to the tank. The reservoir is a white tank with a bottom connected to the pump. Algae solution is pumped from the lowest position to the pipe system with a total length of 120m to the highest position, then the algae is poured into the tank system. The continuous mixing process is maintained by a 375W centrifugal pump at a speed of 0.4-0.5 m/s.

Step 5, operate farming. After the culture system has been prepared, the algae seed is supplied to the systems with clean treated seawater, ensuring that the initial density is from 10 to 15 million tb/ml after the seed is calculated. Supply mixed nutrient medium f/2 at the rate of 1ml/l. Check the flow velocity, control the velocity in the pipe at 0.4 - 0.5 m/s.

Step 6, take care. Regularly check temperature, light and pH in culture systems twice a day. Maintain pH from 7.5 - 8.5 by adding CO2. The nutrient medium f/2 is added periodically every 3 days at a dose of 1ml/l of culture water.

Step 7, harvest. After reaching an average density of about 90 - 120 million tb/ml (nylon bag system), 200 - 250 million tb/ml (tube system), algae cultured in the systems is harvested by using a suction pump at the rate of 10% day or 30%/3 day. Add new water to the system. When the algae population has a density below 80 million tb/ml, 100% harvest is carried out.

Algae, after being collected from the system, are flocculated, deposited, then filtered or centrifuged to form a paste.

Besides the Research Institute for Marine Fisheries, many units and businesses have also focused on the technology of microalgae farming for aquaculture in recent years. Photo: NNVN.

Practical application

The high density of Nannochloropsis oculata seaweed biomass has many advantages such as limiting contamination and reducing production costs. The research results show that the spring time - February or March - will be most suitable for high-density algal biomass culture in simple photo biosystems.

The maximum density was 133.56 x 106 tb/mL (0.56 g/L SKK) in the PC cylindrical photosystem; 121.37 x 106 tb/mL (0.51 g/L SKK) in the NiL photosystem; 98.37 x106 tb/mL (0.41 g/L SKK) in the PE cylinder system; 72.20 x106 tb/mL (0.30 g/L SKK) in the BK tank system and 58.70 x106 tb/mL (0.24 g/L SKK) in the RW tank system.

Culture of Nannochloropsis oculata algae in outdoor nylon bags can extend the culture period to 17 days and reach a maximum density of 38.85±1.28 × 106 tb/mL while the algae cultured in the composite tank degraded more rapidly and reached a density of 20.70±1.01 × 106 tb/mL on day 9 of the culture cycle.

In outdoor culture conditions, with the culture volume in the composite tank from 50 - 1,000l, the population of Nannochloropsis oculata is indifferent and reaches the maximum value ranging from 27 - 28 × 106 tb/mL. The Research Institute for Marine Fisheries recommends that springtime in the summer with high-temperature conditions, algae should be cultured in composite tanks with a short culture time and large volume. In contrast, in low-temperature conditions, it is possible to grow algae biomass in plastic bags.

Translated by Phuong Ha

/2025/05/25/4127-3-073637_820.jpg)

(VAN) Thanks to the promotion from an FAO-implemented project, vegetable production in greenhouses in Moc Chau has seen strong development, from 1.5 hectares in 2021 to nearly 50 hectares in 2024.

(VAN) FAO has recently supported USD 140,000 to implement the project 'Risk mitigation human-animal interface risks through disease control initiatives in pig farming.'

(VAN) The People's Committee of Tra Vinh province has approved an adjustment to the investment policy for the Green Hydrogen Plant project, increasing its area to approximately 52.76 hectares.

![Reducing emissions from rice fields: [2] Farmers’ commitment to the soil](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/05/05/dsc08881jpg-nongnghiep-140632.jpg)

(VAN) Clean rice cultivation model in Thuong Tan commune, Bac Tan Uyen district, is assisting local residents in achieving sustainable agriculture by substantially reducing costs, increasing productivity, and protecting the environment.

(VAN) At the conference to disseminate Resolution No. 68, AgriS introduced its digital agricultural ecosystem and reaffirmed its commitment to accompanying the Government in promoting private sector development and sustainable agriculture.

(VAN) 'Blue Ocean - Blue Foods' initiative is designed to restore marine ecosystems and establish sustainable livelihoods for local communities by cultivating a minimum of 1,000 hectares of cottonii seaweed in the first three years.

/2025/05/21/4642-3-112707_603.jpg)

(VAN) The V-SCOPE project has made direct contributions to three out of six pillars of the Comprehensive Strategic Partnership between Vietnam and Australia.