May 16, 2025 | 12:05 GMT +7

May 16, 2025 | 12:05 GMT +7

Hotline: 0913.378.918

May 16, 2025 | 12:05 GMT +7

Hotline: 0913.378.918

Ricky Farm Group JSC's farm is invested according to the most advanced model in the world. Photo: Quang Yen.

In recent times, many domestic livestock enterprises have deployed the application of technology in livestock farming to increase productivity and quality, prevent diseases, and ensure environmental hygiene.

However, in addition to the quality of pig breeds and genes, the arrangement of barns and monitoring technology equipment also contributes to improving the quality of the pig herd as well as serving statistical work in a scientific and methodical manner.

Ricky Farm Group JSC (Buon Ma Thuot city, Dak Lak) is operating three farms with a scale of 96,000 pigs/year in Dak Lak and Gia Lai. To achieve successful farming, the company has applied many technologies to pig farming.

Mr. Hoang Thanh Tung, Director of Ricky Farm Group JSC, said that in terms of barn design, Ricky Farm’s farms are implemented according to the most advanced and modern models in the world, with construction standards meeting relevant Vietnamese norms and standards.

Barns are arranged at a distance of 12 meters to ensure isolation and local treatment when a disease epidemic occurs. At the end of each farming barn, close to the ventilator, there is an isolation cell to take care of and treat sick pigs to help them recover quickly and not cause infection to other pigs during the farming process.

The barn is equipped with a heat and humidity sensor system to help control microclimate conditions and temperature and humidity thresholds for optimal development of the pig herd. When the temperature is high, the cooling water pump system and exhaust fans will be activated to help maintain the appropriate temperature and humidity in the barn and ensure stable maintenance, thereby ensuring the pigs’ health. This minimizes the conditions for disease outbreaks that affect the growth of the pig herd.

In particular, in terms of disinfection, every day when it is time to work, all workers involved in taking care of the pig herd will go through the technical room and continue to be disinfected and change personal labor protection before entering the livestock area.

When it's time for a break, workers are arranged with a break room and a dining area that are completely isolated, and even all food is irradiated with UV rays to ensure that there is no risk of any pathogens affecting the livestock.

The barns have an advanced and separate design. Photo: Quang Yen.

The waste treatment area and farming area also have a separate isolation wall to ensure independence and avoid the possibility of infection.

Ricky Farm Group JSC also applies automatic feeding and animal control technologies. The entire farm is designed with an automatic feeding system. Of which, trucks transport pigs in specialized tanks and pump them into total Silos containing bran. The bran trucks run outside the farm fence and pump bran into total Silos.

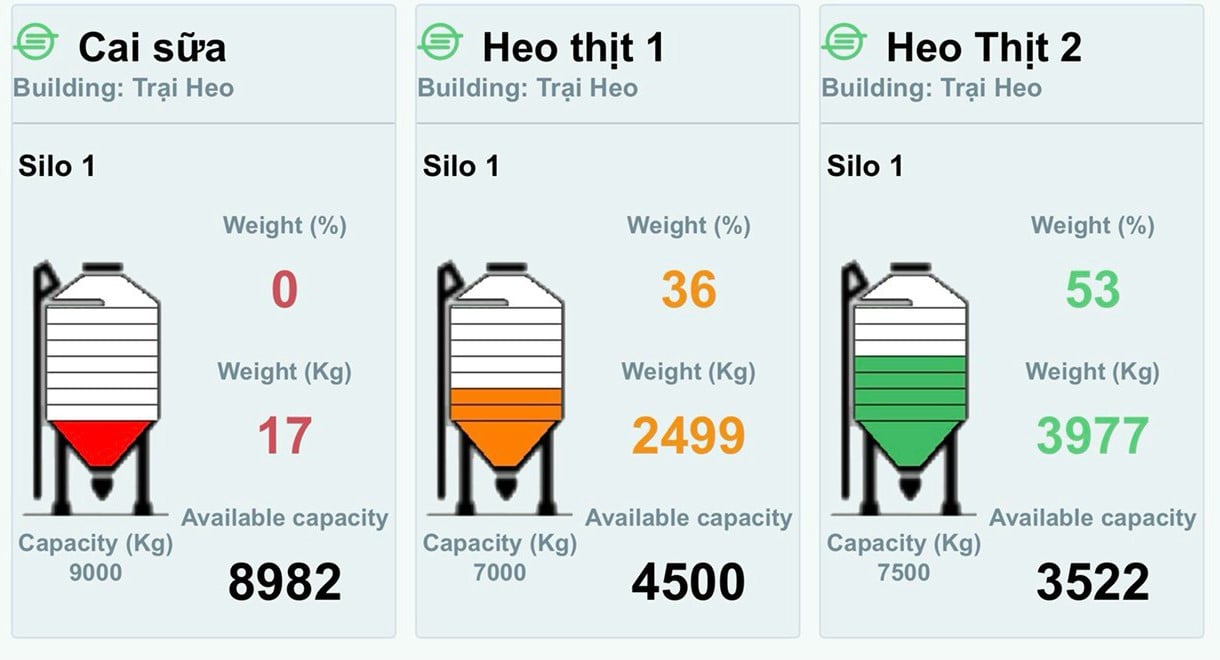

At this time, the total Silos are controlled to pump bran into bran silos at the top of the barn, and thereby, this amount of bran is pumped straight to feeding troughs by Simens PLC PIC s71200 control panels with specialized software. In addition, the system of automatic bran weighing and bran distribution will statistically and directly transfer data via the Ethernet network as well as the Internet so that office executives can grasp specific information.

Feed is put into the total Silo and then distributed to the barns. Photo: Quang Yen.

Ricky Farm Group JSC applies Pig Pro software to manage livestock. Through this software, it is easy to determine from which hatchery the pig litter is imported, raising time, amount of bran used, volume of pigs exported, and types of vaccines used, thereby making it easy to trace, as well as evaluate livestock efficiency and related costs.

As for wastewater, the treatment system uses two-step A/O technology with a USAB anaerobic tank or two-step A/O combined with a physicochemical cluster. Depending on farming conditions, a system of farming barns on a woven floor and a manure-draining tunnel can be applied, helping save water for cleaning barns and bathing pigs, thereby minimizing the amount of wastewater. After being treated, wastewater can be recirculated to participate in cleaning barns and in closed circulation without being released into the environment.

According to Mr. Hoang Thanh Tung, the application of technology in livestock farming helps simplify management procedures, quickly process statistics, and improve the quality of the pig herd.

The software interface for managing bran in Silo to distribute to the barns. Photo: Quang Yen.

"Feeding the pigs is implemented by general vehicles without driving directly into the farm, so it is possible to avoid the spread of diseases. In addition, labor costs are saved. That is because each farm consumes more than 35 tons of bran every day, but when applying technology, 1,000 animals only need one person involved in the operation. If information technology is not applied, the amount of labor used is very large.

With the application of science and technology to controlling growth conditions, the death rate is very low, even less than 1%, so economic efficiency is high. When the pig is sold, it has a large weight, develops evenly with beautiful skin, and meets the partners' requirements," said the Director of Ricky Farm Group JSC.

Translated by Huyen Vu Thu

(VAN) Cold-barn systems efficiently manage environmental and temperature conditions, which aids in the prevention of respiratory diseases in pigs and protects them from the vectors that transmit African swine fevers.

(VAN) To tackle challenges, the project 'Addressing key technical bottlenecks in the grouper supply chain in Vietnam' has been underway since 2024.

(VAN) The project 'Disease-Resilient and Sustainable Cassava Production Systems in the Mekong Region', funded by the Australian Center for International Agricultural Research (ACIAR), is being implemented from 2024 to 2028.

(VAN) Data from 10,000 farming households will help professionalize production organization and support the implementation of the One Million Hectares Program for High-Quality, Low-Emission Rice Cultivation.

(VAN) FAO Director-General QU Dongyu marks International Day of Plant Health at NENA conference.

(VAN) Deputy Minister of Agriculture and Environment Hoang Trung affirmed that floriculture and ornamental plants are a growing industry that receives significant global attention.

(VAN) The three staple crops dominating modern diets – corn, rice and wheat – are familiar to Americans. However, fourth place is held by a dark horse: cassava.