May 21, 2025 | 10:07 GMT +7

May 21, 2025 | 10:07 GMT +7

Hotline: 0913.378.918

May 21, 2025 | 10:07 GMT +7

Hotline: 0913.378.918

In the agricultural development strategy in Vietnam, cassava is rapidly changing its role from a traditional food crop to an industrial crop. It is also a suitable plant for barren lands with high competitiveness.

The global integration is expanding the cassava market, creating opportunities for manufacturers that process starch and starch modified by chemicals and enzymes... to contribute to the economic development of the country.

Dr. Luong Huu Thanh, Head of Department of Environmental Biology, Institute of Agricultural Environment. Photo: Bao Thang.

However, as investment is only focused on improving productivity and quality of products, the issue of managing and controlling waste in the production of tapioca starch has not received proper concern. Such an issue emerges right from the design of cassava starch processing plants and can lead to environmental pollution.

Results of inspection and assessment for the level of environmental pollution due to the influence of cassava starch production and processing activities at a number of factories located in the provinces of Dak Nong, Dak Lak, Nghe An, Ninh Binh, Yen Bai.... shows many problems, such as untreated smoke and dust and solid waste causing stench.

Additionally, physical, chemical, and biological parameters in the wastewater treatment system of those factories all exceed the allowed threshold, causing serious pollution to the surrounding ecological environment.

The process of processing cassava starch produces a huge amount of waste, as the skin accounts for 20-35% of the total weight of the tubers after preliminary processing. On average, it takes 3.5 - 4 tons of raw materials and 7-8 m3 of wastewater to produce 1 ton of starch.

The natural process of converting wastes from cassava processing plants causes odors, rot, air, soil and groundwater pollution as well as affects public health. If wastewater is not collected and treated, the decomposition of natural organic compounds will produce H2S, NH3, CH4... causing unpleasant odors.

Wastewater after cassava starch production has typical properties such as low pH, high concentration of organic matter that is many times higher than environmental standards and technical regulations, causing environmental pollution.

Cassava processing line at a factory in Kon Tum province. Photo: NNVN.

From this situation, a group of researchers led by Dr. Luong Huu Thanh from the Department of Environmental Biology of the Institute of Agricultural Environment (Vietnam Academy of Agricultural Sciences) have conducted a research to select a set of biologically active microbial strains that help to decompose effectively carbon-rich organic compounds, insoluble phosphate compounds, bound nitrogen compounds, and sulfur containing compounds used in waste treatment after cassava starch processing.

Based on the density of microorganisms (Koch method) and the method of culture on specific agar media, the research team have calculated the number of microorganisms per ml or per gram of sample through the number of colonies growing in the media dishes.

The research team have identified a combination of 3 strains of microorganisms (SHX 02, SHB 18 and SHV 73) with activity in carbohydrate metabolism, Ca3(PO4)2 decomposition and free nitrogen fixation activity used in the treatment of organic compounds used in converting cassava waste into bio-organic fertilizer.

Microorganism strains included in the study have the ability to grow and develop under the same conditions without either competing or inhibiting each other. The density of selected microorganisms under mixed and individual conditions did not differ.

After 3 months of storage, the cell density was stable at > 108 CFU/g. The evaluation results showed that the biological activity of microorganisms used in the study did not change compared to the original. In addition, this group is not included in the list of microorganisms restricted from use of the European Union.

With the goal of producing microbial products to convert cassava waste into bio-organic fertilizer, the group has also studied some suitable conditions for the process of biomass multiplication of microbial strains such as pH, temperature, environment, ratio of grade 1 varieties, air, biomass collection time... from which the appropriate technical parameters for the process of biomass multiplication of microbial strains are given.

Cassava starch processing often causes heavy environmental pollution, so it is necessary to find solutions in converting cassava waste into microbial organic fertilizer. Photo: NNVN.

The checking of the quality of microbial biomass has shown that the density of microbial strains used in the study reached 108 - 109 CFU/ml and biological activity remained unchanged compared to the original variety. That proves that the technical parameters that have been studied are suitable for the process of multiplying the biomass of microbial strains in the production of laboratory-scale inoculants.

The team piloted and built a model in the treatment of waste at Elmaco Ninh Binh Tapioca Starch Processing Factory to evaluate the effectiveness of microbial products in converting cassava waste into bio-organic fertilizer.

Translated by Phuong Ha

(VAN) Facing the threat of rabies spreading to the community, Gia Lai province urgently carries out measures to vaccinate dogs and cats on a large scale.

(VAN) Disease-free livestock farming not only protects livestock herds but also stabilizes production and livelihoods for many farmers in Tuyen Quang.

(VAN) Japan's grant aid project contributes to capacity building, promoting organic agricultural production, and fostering sustainable community development in Dong Thap province.

(VAN) For years, the CRISPR-Cas9 genome technology has been reshaping genetic engineering, a precision tool to transform everything from agriculture to medicine.

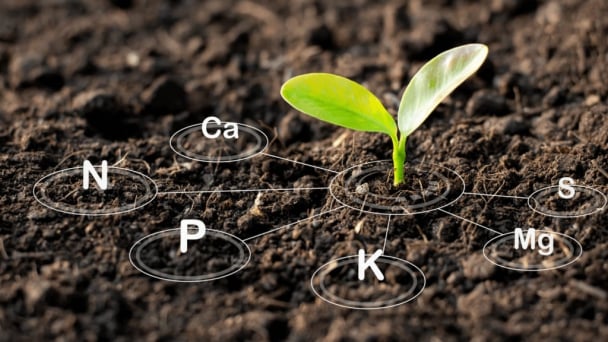

(VAN) Vietnam aims to become a 'leader' in the region in the capacity and managing effectively soil health and crop nutrition.

![Reducing emissions from rice fields: [Part 1] Farming clean rice together](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/05/05/z6509661417740_a647202949c539012a959e841c03e1d3-nongnghiep-143611.jpg)

(VAN) Growing clean rice helps reduce environmental pollution while increasing income, allowing farmers to feel secure in production and remain committed to their fields for the long term.

/2025/05/19/5136-1-144800_230.jpg)

(VAN) The Nghe An Provincial People's Committee has just approved the list of beneficiaries eligible for revenue from the Emission Reductions Payment Agreement (ERPA) in the North Central region for the year 2025.