June 15, 2025 | 20:23 GMT +7

June 15, 2025 | 20:23 GMT +7

Hotline: 0913.378.918

June 15, 2025 | 20:23 GMT +7

Hotline: 0913.378.918

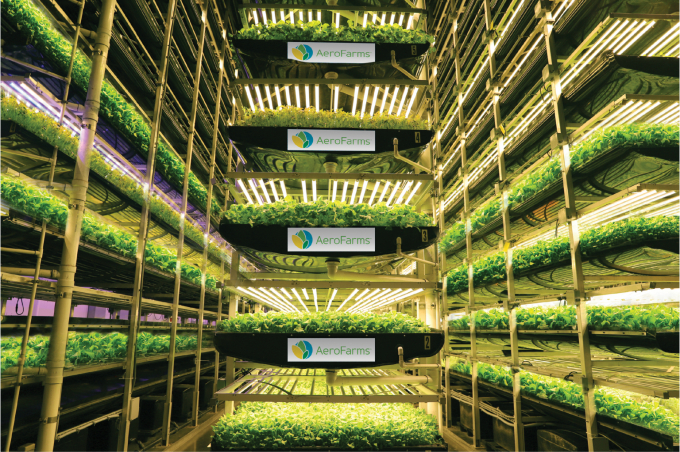

AeroFarm in the UAE for vertical farming. Photo: The Spoon

The biggest news is that the company is going public. In March, it announced a merger with a blank-check firm, Spring Valley Acquisition Corp., that will see the company traded publicly later this year under the ticker ARFM. Also in March, AeroFarms announced a research and development partnership with Hortifrut to push vertical farming technology into the lucrative $39.8 billion berry market, reducing its dependency on revenue from leafy greens. And in July, AeroFarms rebranded its Dream Greens produce line to AeroFarms to capitalize on its name recognition. At the same time, it expanded into five new leafy green products: Baby Bok Choy, The New Spinach, Micro Arugula, Micro Broccoli, Micro Kale and Micro Rainbow Mix. And in August, AeroFarms announced another partnership with Nokia Bell Labs, the New Jersey-based historic scientific research firm, to take its technology to the next level with increased networking, advanced autonomous systems, machine vision and machine learning technologies.

The company is obviously picking up steam. The public market offering and the capital gained during the process will be crucial for AeroFarms to reach the next level of its growth and to achieve several strategic expansions, including improving operational and energy efficiency, adding into new products (right now it’s focusing on berries), and maintaining its social impact.

"We told investors, we view this as a long-term industry," CEO David Rosenberg said. "It is going to be massive. We feel we have a strong leadership position in the industry from a technology standpoint. So how do we build upon that and really double down on the tech producing [capital expenditures], reducing [operating expenses] and improving quality as well as new varieties of plants on this platform."

AeroFarms was founded in 2004, and its products are sold in 200 grocery stores across the Northeast including Whole Foods. It operates one vertical farm in New Jersey, with more on the way. AeroFarms is breaking ground on a facility in Abu Dhabi, pitched as the world’s largest vertical farm, as well as one in Danville, Virginia. Along with the publicly announced farms in Abu Dhabi and Danville, AeroFarms plans to build 16 more farms with the capital it’s raising, using a slightly different strategy than the company’s previous build locations.

"It’s not where the mouths are, but where the produce distribution centers are," Rosenberg said. "So we can sell to a surrounding number of cities. We’ve gone from a lens of hyper local to a more looser definition of local."

AeroFarms uses aeroponics, a soilless way of growing produce that uses mist to cut down on water usage by 95 percent; it plants seeds in cloth made from recycled plastic bottles. Using LED lights, the vertical farms draw on specific wavelengths to maximize efficiency of the plants’ photosynthesis.

The vertical farming industry, already an important part of the food supply chain, is poised to explode. According to a 2020 report by the World Wildlife Fund, indoor farming is projected to have a combined annual growth rate of more than 24 percent between 2018 and 2024, hitting $3 billion in revenues worldwide in 2024. The challenges and opportunities faced by AeroFarms over the next few years will inform the vertical farming playbook for its followers.

Energy is the next big hurdle

The SPAC merger is expected to bring AeroFarms $317 million in cash, on top of the $80 million the company already has, to scale and expand into new geographies. According to Rosenberg, the company focused most of the last 15 years on innovating its technology, seeds and plants. He is confident its technology can support a massive jump in demand and commercialization.

But the process of scaling up vertical farming isn’t without controversy. A World Wildlife study that compared the life cycle assessment of lettuce grown traditionally in California and transported to St. Louis against indoor farming solutions based in St. Louis — including greenhouse hydroponically grown lettuce, greenhouse aquaponically grown lettuce, indoor vertically farmed lettuce, hydroponically grown lettuce and indoor vertically farmed, aquaponically grown lettuce — found that the energy required to run the lights, irrigation and automation for all the indoor solutions resulted in an overall higher climate impact than the traditional farming method.

"Energy stands out as one of the bigger hurdles facing the [vertical farming] industry," said Julia Kurnik, director of innovation startups at WWF and author of the study. "Because it already is making great gains around things like water use, pesticide use, food loss and food waste. So it’s doing wonderful things there."

According to Kurnik, hydroponics and aeroponic farming use less water and don’t degrade soil like traditional farming, but for vertical farming to become environmentally sustainable on a carbon emissions level, these systems need to source electricity from renewables such as solar, wind or hydro.

But simply hooking up a vertical farm to solar or wind power won't solve the problem. Manufacturing solar panels is also an environmental strain due to the materials mined and energy used to make the solar panels. Like Kurnik said, everything that produces energy has to be built. And on the business side, AeroFarms said it’s very difficult for the company to find locations that have access to 100 percent renewable energy.

According to Rosenberg, access to a greener grid is part of AeroFarms’ weighting process for picking new locations for farms, but it can’t be a dealbreaker. For example, Danville relies heavily on nuclear and natural gas for energy, which is one reason AeroFarms decided to build there. Rosenberg also hopes AeroFarms will start to focus on places and cities that have access to hydropower.

But both Kurnik and AeroFarms CTO Roger Buelow agreed that one of the main goals for both the industry and AeroFarms specifically should be reducing the energy intensity of vertical farm growing.

"Let’s be more efficient," Buelow said. "Let’s make sure we are getting the most pounds per square meter per photon we can get. So that we’re really being good stewards with that energy. And we’re making sure that every photon gets to do its job."

One way AeroFarms does this, according to Buelow, is to put a lot of effort into making sure it uses the most efficient LED lights. But Rosenberg emphasizes that there is more to the environmental picture than just energy usage. He notes that aeroponic farming doesn’t use pesticides, herbicides or fungicides, which all have embodied energy in their production and produce degradation effects on the environment.

"There’s the environmental picture. There’s the energy side. There’s the pollution side. There’s the soil degradation side. There’s the water usage side. The water contamination side. There’s the food waste side," he said. "It’s part of a much broader narrative in assessing what’s good or what’s not as smart for the environment."

Working on expanding crop offerings

According to the WWF study, energy represents about 25 percent of the operating costs for vertical farms, and those costs have limited what is profitable to grow in contained-environment agriculture.

"I’ve seen pretty much anything, even fruit trees growing in these systems," Kurnik said. "But it isn’t cost-effective or energy-effective. You would spend so much energy growing them, it would bring a large environmental footprint, and it would become too expensive for the farms to sell that produce. So to see the entire industry scale and be able to grow a much greater variety of things and therefore capture all the benefits that these farms do bring, we need to figure out how to lower and/or green that energy footprint."

AeroFarms is working on breaking out of the leafy green market and making some of those more energy-intensive crops profitable. The company has grown 550 varieties of plants in at least the research phase and is participating in a trial of growing a pharmaceutical ingredient for a drug. But the most likely success story will be the berries it hopes to cultivate working alongside Hortifrut.

"[The partnership] is a great example of how we really think of ourselves as a platform," Rosenberg said. "And how we work on this platform to solve broader problems in agriculture."

Berries are a fickle fruit in the agriculture world. Berries are part of the Dirty Dozen, a list of 12 produce types created by nonprofit The Environmental Working Group that use a lot of pesticides. They are also a high-demand product that people want year-round but that only grow best in summer months, leading to massive transportation costs (both financially and environmentally) as the industry ships berries from farther away places to meet this demand. With that in mind, berries are a high-value crop that could make the investment on the vertical farming side worthwhile for businesses such as AeroFarms.

"It’s local. It’s perishable. There’s a reliable demand. There’s a need for consistency. There’s a need for pesticide-free, herbicide-free," said AeroFarms CFO Guy Blanchard. "There’s many, many markets that look like they could very well make sense [for vertical farming]. We’re at the forefront of looking for those types of crops and markets and finding ways to deploy the technology to address those markets."

One example of that initiative: AeroFarms is also a founding member of Precision Indoor Plants (PIP), a joint venture between The Foundation for Food and Agriculture Research and other participants including BASF, Benson Hill, FFAR, Fluence, GreenVenus and Priva. The consortium is working on genetically adapting seeds for optimized indoor growing, improving light recipes, advancing speed breeding technology and altering the chemical makeup of plants to improve flavor, nutrition and medical efficacy.

"The broader world of vertical farming will have access to all those genetics, and we’ll all be able to grow stronger plants that really make the best use of the features of vertical farms," Buelow said.

PIP and AeroFarms plan to share their findings and innovations with the broader vertical farming community so every business in the industry can operate as efficiently as possible.

"I do think there is a lack of knowledge sharing and best practices across the industry," Kurnik said. "Because it is a bunch of startups. It is very nascent. I think the entire industry could benefit from sharing and establishing metrics and a baseline to figure out how to improve."

Balancing automation alongside social goals

The sustainability of farming and food are huge social issues as much as they are environmental ones. According to Rosenberg, one reason AeroFarms chose to locate a farm in Danville was because of the social impact it could make there. The city is 51 percent African American and has a relatively higher poverty rate than its neighbors.

By entering an economically depressed city, AeroFarms can address food deserts and help alleviate them by providing locally sourced food and creating jobs. The Danville operation will employ about 100 people from the community, according to Rosenberg. "We want to go into those communities and inspire those communities," he said.

AeroFarms also supports a past offenders program that started in 2016 and provides employment for 15 formerly incarcerated people so far.

Automation is coming, and it is one way AeroFarms will decrease costs. But that could undermine the jobs added by the company in the future. Right now, the company automates the seeding process, but the seedlings are placed in trays manually. The loading, unloading, harvesting and packaging is automated but pockets of manual work are needed as well. AeroFarms wants to use the best technology while still providing jobs, according to executives.

"Obviously, our next farms are going to be more automated, much more automated and that innovation is something we are proud of," said Diego Rivera, Aerofarms’ master grower. "But even with automation, nothing is going to replace the human eye. Some key positions are going to be still there."

So it’s going to be about retraining. According to Rivera, Aerofarms has programs in place that create conditions for people to stay at the company by promoting people from within.

"Our approach is going to innovate and continue to work to bring our workforce along with us," Rosenberg added. "How do we train for those next skills? How do we get them to understand how to use those controls so they could apply their contribution in a higher level way? We’re constantly training them to be ready for the next challenges."

To provide employees with the opportunity for upward mobility, AeroFarms offers computer literacy programs and financial literacy workshops. According to Rosenberg, vertical farms are often a collision of education levels; highly educated engineers working alongside farm labor.

"So how can we get the highly educated workforce to work with our frontline workers to teach them these skills and help form that sense of community," Rosenberg added.

It’s clear vertical farming sits right in the middle of many of the largest issues facing our economy and our planet. AeroFarms is trying to tackle a lot of them; everything from food insecurity to energy usage to job sustainability. Succeeding could create a path leading others towards a sustainable and equitable economy of the future for others to follow, while failing will offer a parable of trying to be all things to all people and biting off more than you can chew.

(Greenbiz.com)

(VAN) Extensive licensing requirements raise concerns about intellectual property theft.

(VAN) As of Friday, a salmonella outbreak linked to a California egg producer had sickened at least 79 people. Of the infected people, 21 hospitalizations were reported, U.S. health officials said.

(VAN) With the war ongoing, many Ukrainian farmers and rural farming families face limited access to their land due to mines and lack the financial resources to purchase needed agricultural inputs.

(VAN) Vikas Rambal has quietly built a $5 billion business empire in manufacturing, property and solar, and catapulted onto the Rich List.

(VAN) Available cropland now at less than five percent, according to latest geospatial assessment from FAO and UNOSAT.

(VAN) Alt Carbon has raised $12 million in a seed round as it plans to scale its carbon dioxide removal work in the South Asian nation.

(VAN) Attempts to bring down the price of the Japanese staple have had little effect amid a cost-of-living crisis.