June 2, 2025 | 10:38 GMT +7

June 2, 2025 | 10:38 GMT +7

Hotline: 0913.378.918

June 2, 2025 | 10:38 GMT +7

Hotline: 0913.378.918

The model of 3-stage shrimp farming with the application of microbiological RAS technology increases the economic value for shrimp farmers in Ha Tinh City. Photo: Thanh Nga.

For many generations, Dong Ghe land in Thach Ha commune, Ha Tinh city, has only been known as a semi-intensive, extensive, small-scale aquaculture area, lacking investment and almost completely depending on the weather.

In the 2020–2021 period, the City Party Committee and the City People's Committee decided to plan and develop Dong Ghe land with support policies on administrative procedures, land leases, seed resources, and techniques to help seafood farmers change production practices and gradually transform to high-tech aquaculture.

According to Mr. Tran Quang Hung, Head of Economic Department of Ha Tinh City, in addition to prioritizing the farming test of some new objects, the city supports the deployment and replication of 3-stage shrimp farming models in the Dong Ghe farming area.

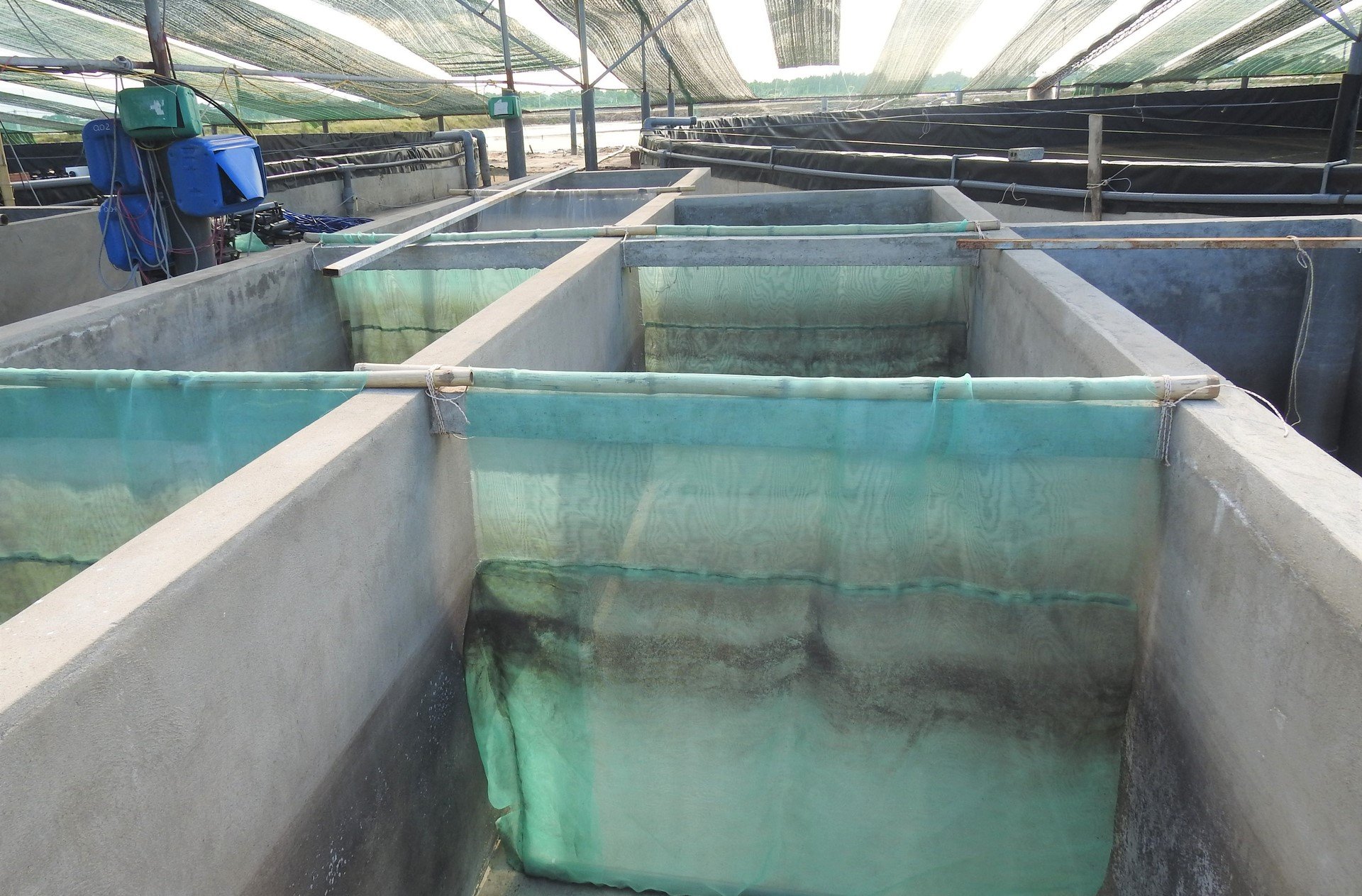

The pond system and water settling tanks are methodically invested in by farmers. Photo: Thanh Nga.

"In 2022, Ha Tinh City continues to issue Resolution No. 54/NQ-HDND on some mechanisms to support the development of urban agriculture and implement the National Target Program on building a new countryside in the 2023–2025 period.

Accordingly, we will focus on encouraging people to develop high-tech intensive aquaculture by guiding them to join linkages, become members of cooperatives, and invest in infrastructure items (ponding, lining canvas, embanking, building membrane houses, etc.). We also give priority to environmental improvement for VietGAP and organic farming and lend capital under priority policies. As of now, the city has more than 5 ha of 3-stage intensive shrimp farming with the application of microbiological technology that gives high economic efficiency, becoming the driving force to continue developing models in the coming time," said Mr. Hung.

As the first model of 3-stage shrimp farming with the application of microbiological RAS technology in the city, in March 2022, three people with the same direction, Mr. Duong Quoc Khanh, Mr. Nguyen Cong Bao, and Mr. Tran Duy Ngoan, jointly invested more than VND 3 billion in shrimp farming in Dong Ghe land.

With the local government's support in leasing 4 ha of land with a term of 20 years, the model owners built a system of shrimp farming ponds lined with tarpaulin, invested in water recirculation settling tanks before putting it into farming ponds, and covered the top of the pond with tarpaulin to prevent heat from shrimp.

The expansion of high-tech shrimp farming models both minimizes disease, protects the environment during the farming process, and improves the quality of post-harvest shrimp products. Photo: Thanh Nga.

According to Mr. Duong Quoc Khanh, the model of 3-stage shrimp farming includes one breeding stage and two farming stages. Accordingly, the pond system is designed with three ponds, including a breeding pond, a farming pond in stage 1, and a farming pond in stage 2. The ponds have an area of 1,500–1,800 m2/pond with a round or square shape, galvanized iron frames to prevent rust, and HDPE tarpaulin lined around. Farmers use microbiological, bactericidal, and algae technology to clean the pond environment.

The model also uses the Recirculating Aquaculture System (RAS) technology, one of the most modern shrimp farming technologies in Vietnam today. The water, after being discharged from the farming pond and the settling pond with a width of about 35 m2, will be treated to completely remove feces and impurities, then continue to be supplied to the farming pond through pipes, becoming a recirculating system.

"The advantages of this system are saving water, the high survival rate of shrimp (reaching over 85%), many farming crops in a year (2–3 crops), the yield higher many times than that of normal farming, the quality of farmed shrimp guaranteed, and importantly, not polluting the environment by thoroughly treating feces, impurities, and bacteria in the water," said Mr. Khanh.

Mr. Duong Quoc Khanh shared that investing in 3-stage shrimp farming requires large capital, but in return, the profit is higher. Photo: Thanh Nga.

In early July 2023, Mr. Khanh's model harvested the first batch of shrimp after 90 days of farming. With an area of 5,000 m2 and a stocking density of 150 head/m2, shrimp grow to a size of 38–40 head/kg, yielding more than 10 tons. With a selling price of VND 165,000/kg, after deducting costs, this model brings a profit of more than VND 600 million. It is expected that in more than a month, Mr. Khanh will harvest the second shrimp crop.

Sharing the reason for investing heavily in 3-stage shrimp farming with the application of microbiological RAS technology, Mr. Khanh said: "The whole Dong Ghe land has only one ditch to both supply water to the farming pond and discharge wastewater after farming into the environment, so the risk of shrimp diseases is very high.

The investment in RAS using microbial products will eliminate all vectors causing shrimp diseases, and importantly, farmers can actively adjust the technical parameters of the water source, thus limiting the use of antibiotics on shrimp. Thereby improving product quality and ensuring food safety and hygiene."

The first farming crop of Mr. Khanh's model brings a profit of more than VND 600 million. It is expected that in more than a month, the second shrimp crop will be harvested. Photo: Thanh Nga.

In addition to Mr. Duong Quoc Khanh's model, Dong Ghe land currently has three more industrial shrimp farming models, which are invested methodically according to the motto that production must be associated with environmental protection. This is an inevitable and appropriate direction in the context of adaptation to climate change, circular agricultural production, and production linkages to improve economic efficiency per unit area.

In the past, high-tech intensive shrimp farming was applied only in sandy farming areas with favorable conditions, such as Cam Xuyen and Nghi Xuan districts, but now, in farming areas with earthen ponds, pond owners in Mai Phu commune, Ho Do (Loc Ha), Ky Ha commune, Ky Thu (Ky Anh), Thach Ha (Ha Tinh City), etc. have also boldly applied and deployed new technologies.

Translated by Huyen Vu Thu

(VAN) Several scientists and farmers are experimenting with soil treatment in some key durian-growing regions such as Cai Lay (Tien Giang), Dak Song, Gia Nghia, and Dak R’lap (Dak Nong).

/2025/05/25/4127-3-073637_820.jpg)

(VAN) Thanks to the promotion from an FAO-implemented project, vegetable production in greenhouses in Moc Chau has seen strong development, from 1.5 hectares in 2021 to nearly 50 hectares in 2024.

(VAN) FAO has recently supported USD 140,000 to implement the project 'Risk mitigation human-animal interface risks through disease control initiatives in pig farming.'

(VAN) The People's Committee of Tra Vinh province has approved an adjustment to the investment policy for the Green Hydrogen Plant project, increasing its area to approximately 52.76 hectares.

![Reducing emissions from rice fields: [2] Farmers’ commitment to the soil](https://t.ex-cdn.com/nongnghiepmoitruong.vn/608w/files/news/2025/05/05/dsc08881jpg-nongnghiep-140632.jpg)

(VAN) Clean rice cultivation model in Thuong Tan commune, Bac Tan Uyen district, is assisting local residents in achieving sustainable agriculture by substantially reducing costs, increasing productivity, and protecting the environment.

(VAN) At the conference to disseminate Resolution No. 68, AgriS introduced its digital agricultural ecosystem and reaffirmed its commitment to accompanying the Government in promoting private sector development and sustainable agriculture.

(VAN) 'Blue Ocean - Blue Foods' initiative is designed to restore marine ecosystems and establish sustainable livelihoods for local communities by cultivating a minimum of 1,000 hectares of cottonii seaweed in the first three years.